How to Bleed a Radiator with the Help of Hot Water Bleed Valves?

March 19, 2020

Four Good Reasons to Install a Quick Exhaust Valve On Your Pneumatic Cylinder

July 4, 2022Pneumatic industry requires a number of valves and pipe fittings. From pneumatic check valves to flow

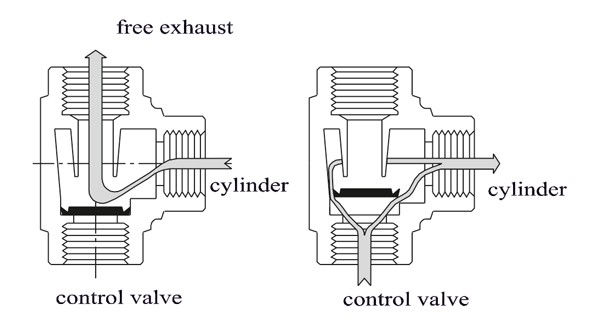

Quick exhaust valves, or QEVs, are designed to increase a cylinder’s cycle speed in a pneumatic system. Installing a pneumatic QEV, either at the rod end or the blind end of a cylinder, will cause rapid extension or rapid retraction. This depends on your requirements.

Upon removal of pressure from the input port of QEVs, backflow occurs at the output. Let’s learn a bit more about these valves and their industrial applications.

Important features of Quick Exhaust Valve

QEVs are used in specific applications; their design allowing for desirable compatibility in a pneumatic system. Their basic features include:

- Ability to allow rapid cylinder return

- Several porting options available

- Direct cylinder mounting option through male pipe thread

- Plated and anodized to resist corrosion

- Critical alignment possible through swivel cylinder port

Industrial applications of Quick Exhaust Valve

– Rapid retraction

In a double acting cylinder requiring rapid retraction, air will be exhausted through a QEV which is coupled closely to the cap end of the cylinder.

QEVs generally have a greater exhaust capacity compared to four-way control valves. An increase in cylinder speed can thus be achieved by using a smaller, less costly control valve.

– Dual Pressure Actuation

In this circuit, a QEV and a three-way control valve is involved. These valves allow quick extension of the cylinder under high pressure conditions. At lower temperatures, retraction can be achieved to save air and increase cylinder life.

Note that the line pressure should at least be 3 to 4 times more than rod end pressure. This differential pressure between the rod and the cap ends allow for an effective working pressure.

– Bi-Directional Control

Maximum control is achieved through this circuit using only a minimum number of valves. A quick exhaust valve is

On the other hand, the retraction of the second cylinder and extension of both these cylinders are controlled by using speed control valves.

At SealExcel, you can find a sufficient lineup of stainless steel QEVs which are durable and manufactured to meet the highest pneumatic industry standards.

A number of different end connections are available; BSP, BSPT, NPT and SAE straight thread. Call now to order QEVs and other pneumatic valves and pipe fittings.