Quick Exhaust Valves And Their Application – An Overview

March 21, 2015Reasons Why Swivel Joints Are Effective

March 20, 2017Quick exhaust valves are special valves which are added to a cylinder to increase the cycle speed of

The Need for Quick Exhaust Valve

Older models of pneumatic cylinders had no possibility of variation of release timings, since it solely depended on the rate at which the air can push back through the control command line to retract the piston in the cylinder. A faster return action of the cylinder can be achieved with the addition of Stainless Steel Quick exhaust valves which is in effect a 3 port tee valve fitting that is added to the inlet of the pneumatic cylinder command line.

How Does It Work?

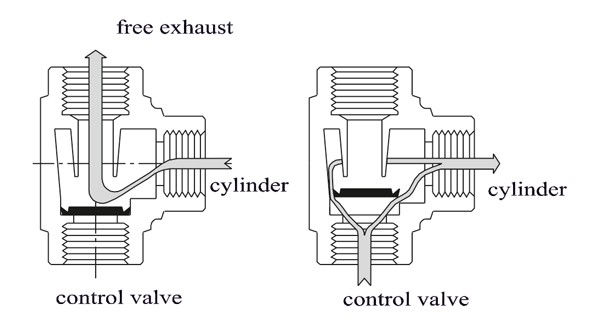

The quick release valve is a 3 port valve fitted before the air supply entry to the cylinder. The free exhaust location marked in the drawing is always open to atmosphere. The control command or air supply source to the cylinder is from the bottom. The air supply or control command usually is from control valves. The port connection to the cylinder is at an angle to the other two inline ports. There is an oil resistant diaphragm of either VITON or Polyurethane chosen as per service medium and port size requirements. The diaphragm acts as the switching element in the valve.

When the air supply or control command is pressurised, air lifts up the diaphragm, closes free exhaust port and fills air into the cylinder. This action leads to movement of the piston in the cylinder (to the right in our case). It remains in this position as long as control command is pressurised.

When the cylinder needs to retract, air from control port is cut. This allows the diaphragm to return to rest position- thus blocking the control port. The air in the cylinder is open to the free exhaust port. Since the free exhaust is exposed to atmosphere, there is quick action during retraction of the cylinder- which effectively reduces cycle time.

Operating and installation parameters:

- Application- inlet to spring return or double acting pneumatic cylinder

- Pressure rating: up to 40 bar

- Temperature rating: up to 120oC

- Size range-

Fractional range: 1/8” through 1/2” pipe thread

- Sealing Material

- Viton for Pipe thread size up to ¼”

- Polyurethane for Pipe thread size above ¼”

- End Connections available-

BSP as standard. BSPT, NPT and SAE threads also available on request.

Why Sealexcel Quick Exhaust Valve?

- Our fittings meet the international specification requirements for high- quality products and testing criteria.

- Sealexcel’s robust and Quick Exhaust Valve applications are designed to be precise and flawless which ensures rapid cylinder return and helps keep the system processes in check.

- Our products come with 3 decades of experience in engineering, product accuracy, consistency, quality and judicious delivery. Our customer care service renders prompt communication with the customers.

Sealexcel is an established name across various industrial sectors owing to the dependability and durability of their pneumatic valve and fittings. Sealexcel’s robust Quick Exhaust valves are durable that adheres to high quality standards making it a leading Quick Exhaust Valve manufacturer.