Application Of Stainless Steel Push In Fittings In Different Industrial Segments

April 22, 2015An Easy Guide To Tubing And Fittings

August 20, 2016Th

The Need for Reliable SS Fittings:

The two primary reasons why stainless steel pneumatic push fittings are so important are:

1. Leakage:

Leakage means a waste of process fluid which could lead to –

- Possible explosive hazards

- Maintenance shutdowns

- Worker safety issues

2. Process Improvement

For any manufacturer, constant innovation and process improvement are of priority, to optimise systems and increase efficiencies. This usually involves modifying the present system which means cutting, tubing, making new lines/bypasses or making auxiliary connections. The quicker these modifications can be made, the faster is the turnaround of the system and lesser is the shutdown time.

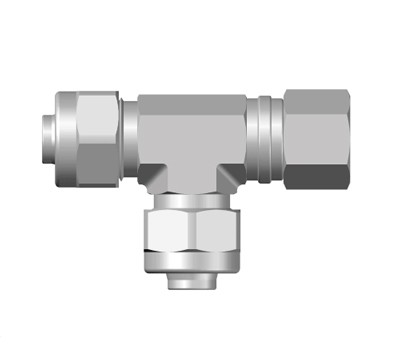

Stainless Steel Pneumatic Push-in Fittings

Sealexcel’s “SS Push-in-fittings” is manufactured with precision and quality, to ensure that they handle corrosive fluids with quick network modification and zero leakage.

Applications

The SS push to connect pneumatic fittings has an extensive usage. It can be used for the following tube materials:

- Semi-rigid nylon tube

- Flexible polyurethane tube

- Fluoropolymer FEP140 tube

- Low-density polyethylene tube

- Stainless Steel and copper tube (when grooved)

- Pressure rating: up to 290 PSI (20 bars)

- Temperature rating: up to 150ºC

- Size range-

- Metric: 4mm through 16 mm tube OD

- Fractional range: 3/16” through 5/8” tube OD

Why Sealexcel SS Push-in-fittings?

- Tubings and semi-rigid pipes can be easily connected by SS Push-in-fittings with just a thrust. The stainless steel pipe fittings have a releasing sleeve inbuilt into the fitting, to warrant no further requirement of additional tools to disconnect the pipe from the fitting.

- The zero leakage is achieved by ‘O’ rings of VITON or EPDM and a locking system with a gripping collet.

- Each Sealexcel Push-in-fittings are made of stainless steel components that are electro-polished so that there is a passive corrosion resistant surface layer of chromium oxide, particularly for handling corrosive medium.

- The stainless steel parts of the fittings conform to ASTM A-479 or ASTM A-182 that guarantees a minimum quality standard.

- Sealexcel has a broad range of Push-in-fittings standard combinations that can be easily modified based on the customer’s requirements. We also make custom made combinations with BSPT end connections, Tees and cross unions.

- Our fittings meet the international specification requirements for high- quality products and testing criteria.

- Our products come with 3 decades of experience in engineering, product accuracy, consistency, quality and judicious Our customer care services render prompt communication with the customers.

- Sealexcel is a leading manufacturer of Stainless Steel Push-in Fittings