Check Valves And Ball Valves: A Quick Guide

August 3, 2016Useful Tips for Setting Bleeder Valves

August 6, 2016Corrosion resistant alloys are incredibly important for the marine industry and used just as extensively.

Able to withstand corrosive surroundings, tough alloys like standard stainless steel and other metals are largely used in applications within this industry.

Why do some alloys prevent corrosion more than others? Will your standard stainless steel valve system be able to withstand the corrosive nature of a particular application?

We find the answers in the following.

Use of Corrosion Resistant Alloys Is the Only Solution

Seawater can wreak havoc on certain metals such as iron. Corrosion is the major issue the marine industry faces as surface of any metal used will be attacked relentlessly. However, metal implements, i.e. tube fittings and valves used for different applications can also perform their best due to certain properties inherent in the alloy.

For instance,Monel and Inconel are two special metals used by the marine industry for special applications due to their high performance and resistance against corrosion. Titanium is another high performing alloy that is used in a number of marine related applications

Types of Corrosion within a Marine Environment

Knowing the types of corrosion that can occur within a marine environment may let us know what type of alloy will do a good job against corrosion prevention for that particular application. The different corrosion types are:

- Intergranular Corrosion

- Stress Corrosion Cracking

- Erosion Corrosion

- Galvanic Corrosion

- Marine Growth

- Crevice Corrosion

Corrosion Prevention with Help from Special Alloys

The reason why corrosion resistant alloys may be the answer to majority of issues faced by the marine industry is simple. Unlike sub-standard alloys, the special implements won’t require consistent maintenance that seems to be an almost regular feature for other metals.

Titanium and stainless steel are metals that work exceptionally well within other industries, including marine.

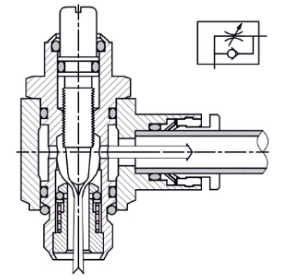

Purchasing a pneumatic check valve or bleed/purge valve from SEALEXCEL is incredibly cost-effective

How to Choose the Right Corrosive Resistant Valve

Harsh seawater environments are divided into three main zones:

Zone One: This covers alloys that are continuously submerged in water or fully immersed. Main elements that affect corrosion level are bio-fueling, pollution, oxygen levels, and temperature.

Zone Two: This covers alloys and implements that are partially covered or immersed in water, such as splash zones and tidal environments. Stainless steel valves and tube fittings work far better in this environment.

SEALEXCEL’s Guarantee: High Quality Stainless Steel Tube Fittings and Valves for Any Application

Unique requirements of the marine industry call for higher quality and reliability in Flow Control valves. All stainless steel implements manufactured by the India-based company are tested according to most recent industrial requirements.

Browse through SEALEXCEL’s extensive product catalogue and select stainless steel valves that are ideal for your application.