Purge Valve: Keeps Your System Clean with One Click

April 3, 2024

Unlock Control Valve Types: Explained in Detail

April 13, 2024In the complex world of machinery and fluid systems, even the smallest components play vital roles. Enter the bleeder valve, often unassuming yet essential for maintaining safety and functionality. While they may be overshadowed by their larger counterparts, bleeder valves are the unsung heroes, ensuring smooth operation and preventing potentially dangerous situations.

This comprehensive guide dives deep into the world of bleeder valves. We’ll explore their various functions, delve into their design principles, and discover their applications across different industries. By the end, you’ll have a newfound appreciation for these tiny titans of pressure control.

Understanding the Essence of Bleeder Valves

At its core, a Bleeder Valve is a simple mechanism that allows for the controlled release of fluids or gasses from a pressurized system. These valves are typically screw-based, with a knob or handle that enables manual opening and closing. The opening size can be adjusted to regulate the flow rate of the released medium.

Bleeder valves serve a multitude of purposes in various systems. Here are some of their key functions:

- Pressure Relief: Perhaps the most crucial function of a bleeder valve is to prevent pressure buildup within a system. By allowing for controlled release, these valves safeguard against potential ruptures or equipment failure caused by excessive pressure.

- Air Removal: Air trapped within a system can lead to inefficiencies and malfunctions. Bleeder valves facilitate the removal of air pockets, ensuring optimal performance of the system.

- System Filling and Purging: Filling a system with fluid or purging it of contaminants often requires controlled introduction or removal of substances. Bleeder valves provide a safe and manageable way to achieve this.

- Sample Collection: In some situations, extracting a small amount of fluid from a system for analysis might be necessary. Bleeder valves offer a convenient way to collect such samples without compromising the integrity of the system.

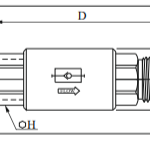

The Design of a Bleeder Valve

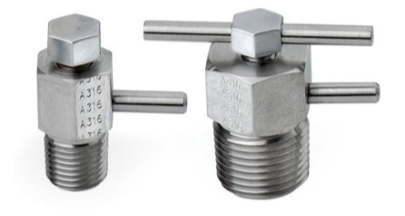

Despite their apparent simplicity, bleeder valves come in various designs to suit specific applications. Here’s a breakdown of their key components:

- Valve Body: The body houses the internal mechanism and provides connection points to the system through threads or fittings. Materials like brass, stainless steel, or even plastic are used depending on the pressure rating and intended use.

- Stem: This threaded shaft connects to the knob or handle and controls the opening or closing of the valve orifice.

- Seat: The seat forms a seal against the opening when the valve is closed, preventing any leakage. Depending on the design, the seat can be integrated within the body or part of the stem.

- Packing: Packing materials like O-rings or gaskets ensure a tight seal around the stem, preventing leaks from the opening mechanism.

- Handle or Knob: This user interface allows for manual operation of the valve, enabling the opening and closing of the orifice.

The specific design of a bleeder valve will vary based on factors like pressure rating, flow rate requirements, and the type of fluid or gas being handled. Some valves might incorporate additional features like a check valve to prevent backflow or a pressure gauge for monitoring system pressure.

Applications of Bleeder Valves: Spanning Industries

The versatility of bleeder valves makes them indispensable across a wide range of industries. Here are some prominent examples:

- Hydraulic Systems: In hydraulic machinery like excavators or forklifts, bleeder valves are used for pressure relief, air removal during system filling, and purging of contaminants.

- Pneumatic Systems: Air pressure systems commonly utilize bleeder valves for pressure relief, removing condensate (water buildup), and introducing lubricants into the system.

- HVAC Systems: Air conditioning and heating systems rely on bleeder valves to purge air pockets from radiators or pipes, ensuring efficient heat transfer.

- Plumbing Systems: Bleeder valves are employed in domestic and industrial plumbing for pressure relief, draining water lines for maintenance, and introducing antifreeze solutions in colder climates.

- Automotive Applications: Vehicles incorporate bleeder valves in braking systems for bleeding air trapped within the lines, ensuring proper brake operation. Similarly, bleeder valves might be present in engine cooling systems for air removal and coolant draining.

This list is not exhaustive, and bleeder valves can be found in countless other applications wherever controlled pressure release or fluid management is necessary.

Selecting the Right Bleeder Valve

- Fluid Compatibility: The valve materials must be compatible with the fluid or gas being handled to prevent corrosion or degradation.

- Connection Type: The valve should have the appropriate thread size or fitting type to connect seamlessly with your system.

- Operating Environment: Consider factors like temperature extremes, vibration, or exposure to corrosive elements that might impact the valve’s performance.

- Ease of Use: Opt for a Bleeder Valve with a user-friendly handle or knob that allows for easy operation, especially if frequent adjustment is required.

Consulting with a qualified professional familiar with your specific application is highly recommended to ensure you select the most suitable bleeder valve.

Installation and Maintenance Tips for Bleeder Valves

Proper installation and maintenance are crucial for the optimal performance and longevity of your bleeder valve. Here are some key points to remember:

- Installation:

- Ensure the chosen valve has the correct pressure rating and connection type for your system.

- Use appropriate thread sealant or tightening techniques to create a leak-proof connection.

- Install the valve in a location that allows for easy access for operation and maintenance.

- Maintenance:

- Regularly inspect the valve for any signs of wear or damage, such as leaks, loose connections, or corrosion.

- Replace worn-out components like O-rings or packing materials to maintain a tight seal.

- Consider periodic cleaning of the valve, especially if dealing with fluids prone to leaving deposits.

By following these simple guidelines, you can ensure your bleeder valve functions reliably for years to come.

Conclusion: The Mighty Bleeder Valve

Often overlooked, bleeder valves play a critical role in maintaining safe and efficient operation across various industries. From preventing catastrophic pressure buildup to facilitating system maintenance, these tiny titans of pressure control are essential for the smooth functioning of countless applications.

The next time you encounter a bleeder valve, take a moment to appreciate its contribution to the complex world of machinery and fluid systems. By understanding their functions, designs, and applications, you can ensure these unsung heroes continue to perform their vital tasks effectively.