Hydraulic Flow Control Valve: Master Fluid Power with Precision

May 15, 2024

Hydraulic Fittings & Connectors: Sealing the Deal

June 4, 2024The lifeblood of countless machines – from towering construction giants to the delicate robotics in a surgeon’s hands – is hydraulic power. But this power doesn’t magically appear; it flows through a network of vital arteries: hydraulic hoses and fittings. These seemingly simple components play a critical role in ensuring smooth, reliable operation by transferring pressurized fluid efficiently.

Let’s delve deeper into the fascinating world of hydraulic hoses and fittings. We’ll explore how they work, the different types available, and the crucial factors to consider when choosing the right ones for your specific needs.

Understanding the Power Flow: Hoses and How They Work

Imagine a robust hose, much like a garden hose but built for a more demanding job. This hose, constructed with layers of synthetic rubber, textiles, and steel wire reinforcement, is designed to handle the high pressures and abrasions encountered in hydraulic systems. The inner tube, typically made of nitrile rubber, is the pathway for the hydraulic fluid – the lifeblood of the system. The outer layers provide strength and protection, ensuring the hose can withstand the pressure without rupturing.

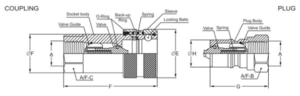

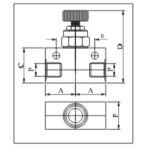

Here’s where the magic happens: the fittings. These metal components connect the hoses to various parts of the hydraulic system, like pumps, valves, and actuators. They come in various shapes and sizes, each designed for a specific purpose. Some fittings have threads for screwing onto components, while others utilize quick-connect mechanisms for faster and easier assembly.

Together, hydraulic hoses and fittings create a sealed system that efficiently transfers pressurized fluid. This fluid, typically oil, transmits power throughout the system, allowing for the precise control of force, movement, and speed in machinery.

A Diverse Crew: Types of Hydraulic Hoses and Fittings

Just like actors in a play, different types of hydraulic hoses and fittings take on specific roles within a system. Here’s a glimpse into the key players:

- Hoses:

- Spiral Four Wire (4SP): A workhorse for medium-pressure applications, offering excellent flexibility and abrasion resistance.

- Thermoplastic Hoses: Ideal for low-pressure applications where weight and chemical resistance are crucial.

- High-Pressure Hoses: Built for heavy-duty tasks, these hoses can handle extreme pressures with their robust construction.

- Fittings:

- Crimp Fittings: The most common type, offering a secure and permanent connection achieved through a specialized crimping tool.

- Flange Fittings: Used for high-pressure applications where easy disassembly might be needed for maintenance.

- Quick-Connect Couplings: Enable rapid connection and disconnection, ideal for applications requiring frequent hose changes.

Choosing the right hose and fitting combination depends on several factors, including pressure requirements, operating temperature, fluid type, and application environment. Consulting a hydraulics expert is recommended to ensure optimal performance and system longevity.

Ensuring Smooth Flow: Installation and Maintenance Tips

Hydraulic hoses and fittings, when properly installed and maintained, become silent partners in ensuring smooth machine operation. Here are some key tips:

- Installation: Always follow the manufacturer’s instructions for proper hose routing, bending radius, and tightening torque for fittings.

- Inspection: Regularly inspect hoses for signs of wear, damage, or leaks. Look for cracks, cuts, bulges, or any abnormal changes in shape.

- Cleaning: Keep the fittings and hose surfaces clean to prevent contamination and ensure proper sealing.

- Storage: Store spare hoses in a cool, dry place away from direct sunlight and extreme temperatures.

By following these simple practices, you can extend the lifespan of your hydraulic hoses and fittings, preventing costly downtime and ensuring the continued smooth operation of your machinery.

Beyond the Basics: Advanced Considerations

The world of hydraulic hoses and fittings extends beyond the fundamental types and maintenance practices. Here are some additional considerations for those seeking a deeper understanding:

- Material Selection: Different hose and fitting materials cater to specific needs. For example, stainless steel fittings might be preferred for applications involving corrosive fluids.

- Compatibility: Ensuring compatibility between the hose, fitting material, and the hydraulic fluid is crucial to avoid chemical reactions that could degrade the components.

- Customization: For unique applications, custom-built hoses and fittings can be a solution.

Conclusion: The Vital Link in a Hydraulic System

Hydraulic hoses and fittings, often taken for granted, play a vital role in the efficient operation of countless machines. By understanding their types, functions, and proper maintenance practices, you can ensure a smooth flow of power and keep your machinery running at peak performance. Remember, these seemingly simple components are the silent partners guaranteeing secured connections and a powerful flow within the hydraulic system.