Ferrule Pipe Fittings: A Simple Guide to Reference

August 22, 2024

Brass Ferrule Fittings: Your Proven Piping Solution

November 9, 2024Industries that operate highly on ferrule fittings include plumbing, hydraulic, and pneumatic systems. These fittings provide an excellent and waterproof seal for joining tubes and pipes. Providing the wide range of ferrule fitting types available, it’s necessary to learn about their various features and applications in order to make informed conclusions.

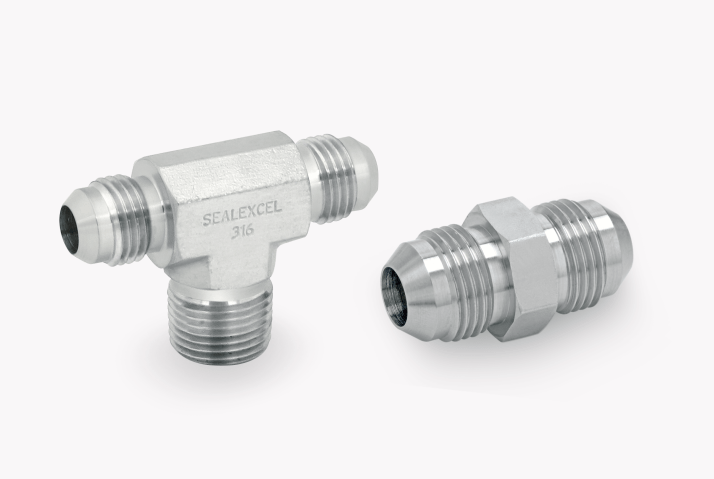

Understanding Ferrule Fittings

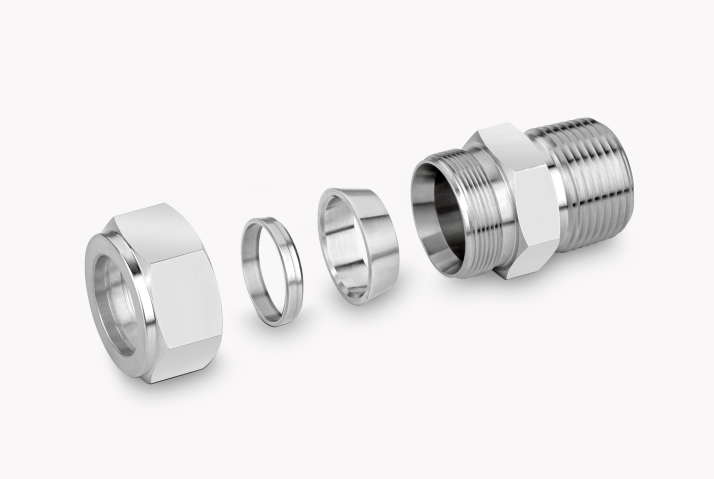

Let’s know the main concept before getting into the many types of ferrule fittings. Usually, a ferrule fitting is made up of two major components:

- Ferrule: A carefully designed ring that, when tightened up, presses against the tube wall.

- Fitting Body: The fitting’s body, which contains the ferrule and offers a threaded connection.

Types of Ferrule Fittings

- Single Ferrule Fittings

Single-ferrule fittings, which create a seal using a single ferrule, are one of the most commonly used types of fittings. They are suitable for many types of applications and are generally easy to install.

- Double Ferrule Fittings

Double ferrule fittings use two ferrules, one on both sides of the tube, to provide a more reliable and secure seal. They are commonly used when vibration is a problem or excessive pressure is present.

- Compression Fittings

Compression fittings are sealed by a compression ring. Due to their ease of installation and reusability, they are a popular choice for many different applications.

- Barb Fittings

The pointed end of a barb fitting creates a mechanical seal by entering the tube wall. For low-pressure applications, they are an easy and affordable alternative.

- Push-to-Connect Fittings

Push-to-connect fittings are easy to place because they don’t require any tools. With a packed process, the tube is sealed simply by adding it into the fitting.

Choosing the Right Ferrule Fitting Type

Keep in mind the following elements while choosing the right type of ferrule fitting:

- Pressure Rating: Verify that the fittings are capable of supporting the highest operating pressure for your system.

- Temperature Range: The fitting must be suitable for the range of temperatures you want to use it at.

- Vibration and Shock: Applications that have to react to high levels of shock or vibration may benefit from double ferrule or compression fittings.

- Tube Material: Your tubes’ materials (such as copper, stainless steel, or plastic) should match the fitting.

- Installation Ease: Take installation flexibility into account, particularly for field applications.

Advantages of Ferrule Fittings

- Reliable Sealing: Ferrule fittings offer an effective and waterproof seal.

- Reusability: Costs can be decreased by reusing a variety of ferrule fitting types.

- Versatility: Ferrule fittings come in a wide variety of sizes and configurations.

- Durability: Ferrule fittings are solid and flexible to challenging situations.

- Ease of Installation: Many ferrule fittings are easy to install and need minimal equipment or expertise.

Conclusion

Knowing the many varieties of ferrules and their specific applications can help you select the ideal one for your project. Consider factors like vibration, temperature, pressure, tube material, and ease of installation to make an informed decision. By selecting high-quality ferrule fittings, you can ensure the dependability and longevity of your hydraulic, pneumatic, or piping system.