The Role of NSF Approved Fittings in Food & Beverage Dispensing Equipment

August 18, 2025

How Threaded Instrumentation Fittings Prevent Downtime in Harsh Industrial Environments

August 22, 2025In the fast-paced world of automation and industrial manufacturing, the choice of materials for pneumatic components significantly impacts efficiency, durability, and safety. Among various options, stainless steel 316L has emerged as the preferred material for pneumatic fittings due to its exceptional performance characteristics. This high-grade alloy offers unmatched corrosion resistance, strength, and longevity, making it an ideal choice for demanding environments. As industries in Mumbai increasingly recognize the benefits of stainless steel pneumatic fittings, manufacturers are shifting from traditional metals to these advanced solutions to ensure higher reliability and safer operations.

Corrosion Resistance and Longevity in Harsh Environments

One of the most compelling reasons to opt for stainless steel 316L fittings is their superior corrosion resistance. Industries such as food processing, dairy, and beverage manufacturing often operate in environments where moisture, chemicals, and cleaning agents are prevalent. Conventional metals tend to degrade under such conditions, leading to contamination, increased maintenance, and downtime. This durability is especially crucial for food-grade stainless steel fittings used in hygienic environments, where maintaining purity and cleanliness is paramount.

Strength and Durability for Heavy-Duty Applications

Industries with high-pressure systems demand robust and reliable fittings that can withstand extreme operational stresses. High-pressure fittings crafted from stainless steel 316L exemplify this requirement, offering high tensile strength that resists deformation and failure. This strength ensures consistent performance in automation-heavy industries, including manufacturing plants and process industries.

Hygiene and Cleanability for Food and Beverage Sectors

In sectors like food and beverage, hygiene is critical. The ability of stainless steel hygienic fittings to withstand rigorous cleaning cycles without corrosion or contamination is a significant advantage. These fittings are designed to meet stringent food-grade standards, facilitating smooth, easy cleaning and preventing bacterial buildup. Quick-connect fittings and food-grade stainless steel fittings are widely preferred for their non-porous surfaces and resistance to corrosion, ensuring safe and efficient processing.

Cost-Effectiveness and Long-Term Performance

The best steel products provide long-term performance

While the initial investment in stainless steel 316L fittings might be higher compared to other materials, their durability and resistance to corrosion make them more cost-effective over time. Reduced maintenance, fewer replacements, and minimized downtime contribute to the overall savings for manufacturers and operators. Additionally, the availability of food and beverage connectors and dairy machine fittings from a reputable pneumatic fittings manufacturer in Mumbai ensures access to high-quality, NSF-approved solutions tailored to industry needs.

Elevate Your Pneumatic Systems with Premium Stainless Steel Fittings

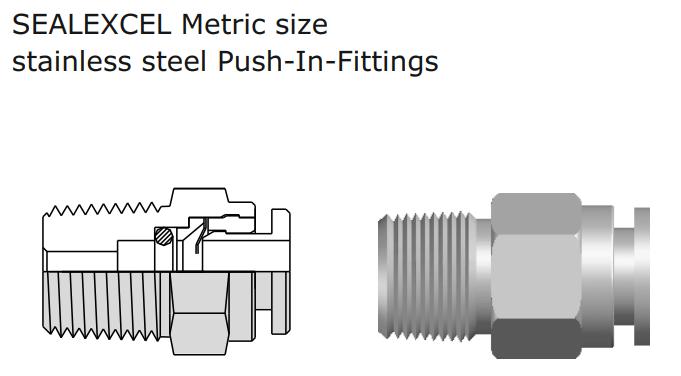

In today’s competitive industrial landscape, choosing the right materials for pneumatic components is vital for operational success. Stainless steel 316L’s corrosion resistance, strength, and food-grade properties make it ideal for a wide range of applications, from food processing to heavy-duty manufacturing. Reaching out to a quick-connect fittings supplier in Mumbai can provide access to top-quality stainless steel push-in fittings and other essential components. Seal Excel offers a comprehensive range of stainless steel pneumatic fittings in Mumbai. Explore how our solutions can improve your operations—reach out to our team today and experience the difference that high-grade stainless steel can make.