We know the importance of design precision and manufacturing accuracy when it comes to industrial valve units and fittings, and that is why we take pride in offering nothing but the most durable and precision accurate units in the industry.

With decades of service, we have established a reliable name for ourselves in the industry, and our hydraulic compression fittings are designed to be as per the industrial standards, ensuring flawless operations and safety across all system procedures.

As Bite-Lok hydraulic fittings manufacturers, we supply units duly checked and analyzed through stringent lab testing procedures for any flaws, before being supplied for a variety of applications in the industry. We take pride in what we do!

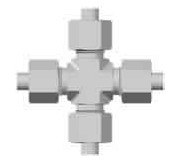

Key Features of Our Din Hydraulic Fittings

Designed to perfection with high quality material, our tube fitting as per 2353, have the following flawless and precision features,

Units are available in a standard stainless steel design.

The Bite-Lok hydraulic fittings are designed to be heat code traceable, which ensures tracking to the certified material test report

Our din 2353 fittings are recommended to be annealed to a seamless stainless steel cold tubing, of DIN 17548 or its equivalent. They have tolerance of DIN 2391 Part 1.

The operating parameters of these Bite-Lok hydraulic fittings have a temperature rating of up to 400OC. it is recommended that for any temperatures higher than these, a due reduction in pressure is required to be taken into complete account.

The temperature rating of the seal material is BUNA-N -35OC and reaches to 100OC. While the FPM Viton is of a -25OC to a 200O C.

The units are available with a range of studs and different port forms. Tightening torques for studs in different thread measurements and dimensions are also available to accommodate all industrial needs.

The units have been designed with a twin biting feature, which ensures that the product edges have safe and firm gripping on the tubing. This ensures leak free connection of components and tubes to the fluid systems.

Click here to access details about pressure ratings of the Bite-Lok tube fitting series.

Our Quality Din Hydraulic Fitting Design

Our hydraulic fittings are designed with a stop edge and twin bite ring, which ensures that the rising force and pressure is duly distributed. As din 2353 fitting manufacturers, we have designed the inner D edge of the ring to increase possible safety of the unit, with reference to the flexure stresses. This results in eliminating any vibration from the biting area of the product. The high quality design helps us ensure,

High level fatigue strength

Resistance to vibration

Reliability for use in high pressure applications

Assurance of operational safety

Sealing efficiency noted to a high degree