Ferrule Fittings Types: Different Types of Fittings

November 5, 2024

Different Type of Hydraulic Connectors. An Overview

November 15, 2024Understanding Brass Ferrule Fittings

Brass ferrule fittings provide a secure and effective way to connect pipes, making them necessary parts of many piping systems. Usually made up of brass, these fittings are strong and able to resist rust, which makes them appropriate for a variety of uses.

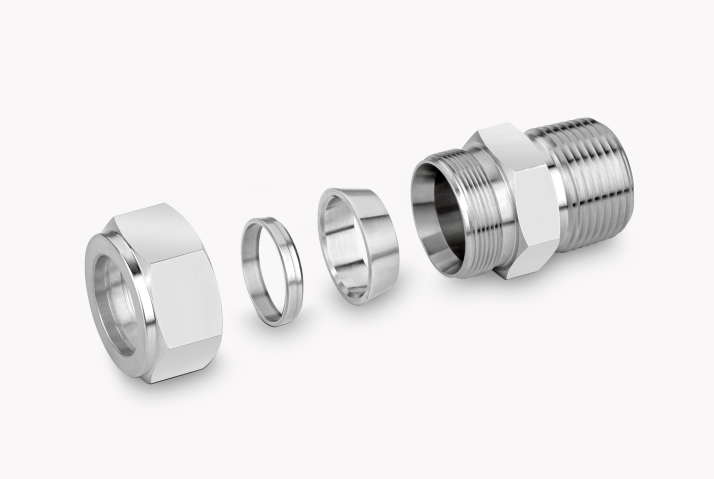

Key Components of Brass Ferrule Fitting

The two primary components of an ordinary brass ferrule fitting are:

- Ferrule: A cylindrical sleeve, usually composed of brass, is pressed or inserted into the pipe after being installed.

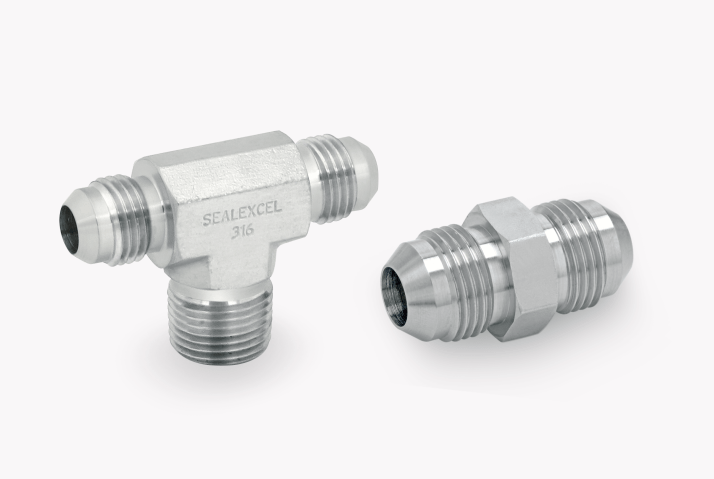

- Fitting Body: The fitting’s main component can take several different forms, including couplings, tees, and elbows.

Types of Brass Ferrule Fitting

Brass ferrule fittings come in a variety of forms, each designed for a particular use:

- Compression Fittings: These fittings create a tight seal by securing the pipe within the connection with a compression ring.

- Crimp Fittings: For this type of fitting to make a lasting connection, the ferrule must be attached to the pipe using an assembling tool.

- Push-Fit Fittings: Since no tools are needed, installing these fittings is simple. A protecting ring holds the pipe in place after it is gently inserted into the fitting.

Advantages of Brass Ferrule Fitting

Comparing brass ferrule fittings with regular screwed fittings reveals several benefits:

- Leak-Proof Connections: Even when the pressure is strong, the ferrule and pipe fit tightly, guaranteeing waterproof connections.

- Quick and Easy Installation: Installing brass ferrule fitting is quick and simple, which saves labour expenses and installation time.

- Corrosion Resistance: These fittings can be used in difficult circumstances because brass has a strong corrosion resistance.

- Durability: Fittings made of brass ferrules are strong and resistant to high temperatures and pressures.

- Versatility: Because they come in many types of sizes and shapes, brass ferrule fittings can be used in a wide range of settings.

Applications of Brass Ferrule Connections

There are many uses for brass ferrule fittings, such as:

- Plumbing Systems: For plumbing system connections in homes and businesses.

- HVAC Systems: For attaching pipes in air conditioning, heating, and air circulation operations.

- Industrial Piping: For joining pipes in manufacturing and chemical processing, among other industrial operations.

- Medical Gas Systems: for attaching pipes for nitrogen oxide and oxygen in medical gas systems.

Factors to Consider When Choosing Brass Ferrule Fittings

The following elements should be taken seriously while choosing brass ferrule fittings for your projects:

- Pipe Material: The right kind of ferrule fitting will depend on the kind of pipe.

- Pipe Size: The fitting’s size is decided by the pipe’s size.

- Pressure Rating: For the intended use, the fitting’s pressure rating should be enough.

- Temperature Rating: The fitting’s temperature rating needs to be appropriate for the operational environment.

- Corrosion Resistance: It is recommended to utilise a waterproof element if the fitting will be exposed to harsh environments.

Tips for Installing Brass Ferrule Connections

Use these pointers to make sure brass ferrule fitting are installed correctly:

- Clean the Pipe: Clean the pipe well to get rid of any size, dirt, or garbage before putting the fitting in.

- Insert the Ferrule: Once the ferrule is entirely placed in the pipe, insert it.

- Crimp or Swage the Ferrule: Put the ferrule on the pipe using a welding or securing tool.

- Tighten the Fitting: To assure a secure seal, tighten the fitting onto the pipe.

- Inspect the Connection: Check any leaks in your connection after installation.

You can make sure your brass ferrule fittings are set up properly and will keep working securely for many years ahead by paying attention to these pointers.

Conclusion

For joining pipes in a range of applications, brass ferrule fittings offer a trustworthy and flexible option. You can choose the best fittings for your project by being aware of the various fitting types and features. Brass ferrule fittings have the ability to offer a long-lasting, leak-proof connection with the right installation.