Three Things You Should Know

September 30, 2016How To: Maintain a Pressure Reducing Valve

October 6, 2016You won’t be able to name one industry that doesn’t install check valves to its operating systems. Yes,

Offered benefits of check valves when it comes to flow control and related operation systems can only be accessed after understanding these industrial valves.

Purchase High Quality Valves for Better Working Industrial Systems

Long-lasting durability, sustainability, and high quality are what you should look for when purchasing check valves. Remember, proper research should be done when selecting check valves (or any other type of valves) as your decision will greatly impact your project and the application the device is required for. Refer to the following important points when choosing a check valve.

Engineers and Managers – Keep This List in Mind When Shopping For Check Valves

Professional installation and maintenance is necessary if you want to ensure longer working of your valves and tube fittings; however the following also works:

- Without check valves, you won’t be able to operate your fluid pumping system efficiently.

- Pipe diameter isn’t the only consideration when it comes to proper sizing. Application and flow are also important factors.

- Water Hammer is a condition that can badly damage pipes. It results due to pressure surge that is caused when slurry or a liquid is forced to change direction or stop suddenly, while in motion.

- The correct check valve can significantly reduce this condition.

- An undersized check valve causes excessive noise, vibration, and high loss in water pressure.

- An oversized check valve causes early wear of valves as well as failure of essential internal components.

- Size does matter! Properly sized check valves will add longevity and durability to not only the valves, but pumps and related components too.

- An energy efficient check valve is one that is properly sized (in any pump fluid flow system) and guarantees the required flow control, while decreasing energy consumption significantly.

- Remember to properly size check valves designed for low flow applications. This will make sure the valve is completely open based on maximum fluid flow.

- Soft seats offer bubble-tight leakage control while metal sealing surfaces allow some leakage to seep through.

Applications One-Directional Valves Are Used For

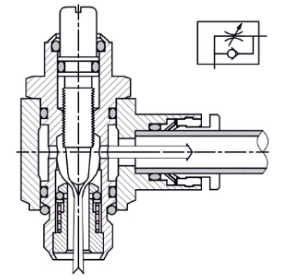

Check valves are usually installed in operations where backflow (liquid, gas) could cause total or partial shutdown of a pump or compressor. Judging from this – check valves are commonly found in gas systems and various other applications where liquid control is required.

These valves can prove to be incredibly useful if implemented for the appropriate projects. This is why understanding what check valves offer is very important as well! Not sure what type of check valve will benefit your project the most? Get in touch with SEALEXCEL and learn all about check valves today!