Benefits Of Using Stainless Steel Valves

March 20, 2020How Ball Valves Work?

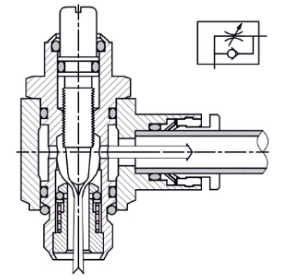

March 20, 2020Check valves are designed to allow passage of fluid in only one direction. This is done in a manner that

These valves are used for different applications in various industries. Specific types of check valves can be used for these applications, including swing check, tilting-disc check, tee-pattern lift check, ball check, and Wye-pattern lift check valve.

In addition to the specific type of valve, other factors influence their suitability for different industrial purposes. These factors prominently include gravity and flow velocity.

Let’s explore how these factors affect industrial usage.

Effect of gravity and flow velocity

The force of gravity has an important role in determining how well a check valve can function. Hence, both location and orientation of these valves must be considered for your required application.

Swing check valves should be located in a manner that their position allows their disc to be closed freely by gravity. On the other hand, both lift and ball check valves must be oriented in a way that the direction of lift remains vertical.

Flow velocity of the concerned fluid—passing through the valve—also has a significant impact.

The valve should be of appropriate size, allowing the fluid velocity to keep the disc open, pressed against the stop. This will reduce disc fluttering, a primary cause of valve failure, and allow it to last longer.

Furthermore, these valves should never be placed immediately downstream of any component which can cause turbulence. This includes control valve, elbow, pump and tee-branch connections.

Adopting the recommended conditions

It is always recommended that you follow manufacturer’s guide, so that the required straight run of pipe is provided upstream of the check valve.

Space and layout restrictions may sometimes not allow you to comply with these recommendations. In such cases, evaluate the alternatives and apply the most reasonable option.

Certain limitations still exist. For instance, swing check valves can only be used in the vertical run if the flow is upward. In addition, both fluid velocity and pressure must be sufficient so that the disc weight can be overcome, allowing it to swing in a fully open position.

In-line ball check valves, in contrast, can be used in both vertical and horizontal lines.

Also, swing valves are not recommended if the flow is low and pulsating. The continuous flapping of the disc against its seat will result in considerable damage to the valve; the swing discs may even come loose at times.

Choose stainless steel check valves which are suitable for various fluid materials and surrounding

Our non-return check valves offer a number of options suitable for multiple industries. Check out various check valves optimized for pneumatic industries and start ordering right away!