Brass Ferrule Fittings: Your Proven Piping Solution

November 9, 2024

Hydraulic System: The Engine of the Machines

November 26, 2024Every hydraulic setup needs connectors to connect components and ensure the smooth flow of fluid within the system. Creating and upkeeping hydraulic systems necessitates knowledge of the kinds of connectors available. This comprehensive guide will delve into the types of connectors present in different forms along with their functions and factors to consider when selecting the most suitable ones.

What exactly do hydraulic fittings entail?

In hydraulic speaking, hydraulic connectors are devices utilised for connecting pipes and hoses to prevent leakage and withstand pressure scenarios of varying levels of pressure. The choice of used is determined by factors such as the application flow characteristics, pressure limits, pressure values, and other relevant considerations.

Types of Hydraulic Fittings

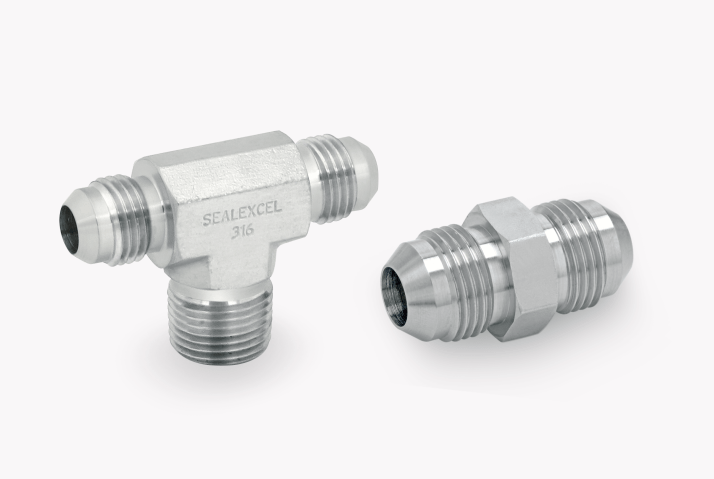

- Flare Fittings: Flare fittings are widely used in systems as they consist of a fitting with a tapered seat and a male fitting with a flared end that tightens against the curved seat of the female fitting when assembled, allowing for easy disassembly and reassembly in various applications.

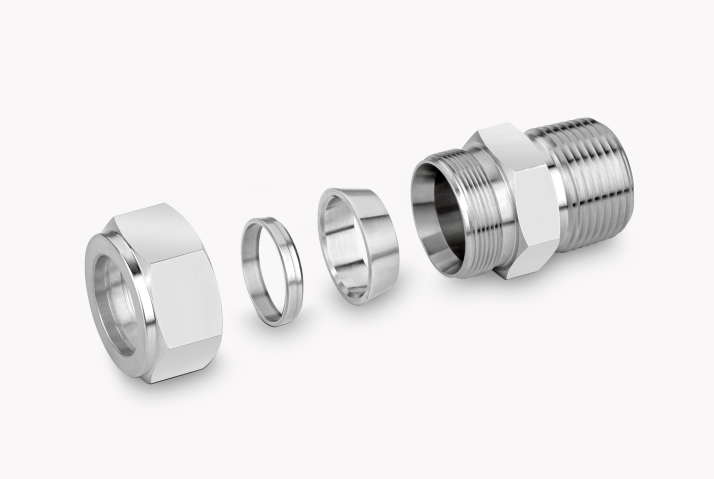

- Compression Fittings: Compression fittings are a type of fitting that connects the tube and fitting using a ferrule or sleeve to create a seal by tightening the ferrule around the tube, making them resistant to stress and vibration commonly used in high-pressure situations.

- O-Ring Fittings: O-ring fittings rely on an O-ring to create a seal between the fitting and the tube. When the fitting is tightened, the O-ring is compressed, creating a seal to prevent leaks. Because of the ease of assembly and disassembly, O-ring fittings are commonly used in low-pressure applications.

- Pipe Thread Fittings: For connecting pipes with threaded ends, use pipe thread fittings. They are available in various shapes, including elbows, tees, couplings, and pipe threads, both male and female. Pipe thread fittings are often used in industrial applications where resistance to high temperatures and pressures is required.

- Swivel Fittings: A swivel fitting enables the flexible connection between parts of a hydraulic system. These are typically installed on mobile equipment, especially agricultural and construction machines. Swivel fittings can be coupled with another fitting type, for example, flare or compression fitting, for the provision of flexible and durable connections.

- Quick-Connect Fittings: Hydraulic parts may be assembled and disassembled fast because of quick-connect wiring. They are often used in industrial machinery as well as in mobile equipment, for instance, where frequent connections and disconnections are required. There exist several types of quick connect fittings, such as threaded, bayonet, and push-to-connect fittings.

Things to Consider When Making a Choice for Hydraulic Fittings

There are several considerations to be made when deciding on hydraulic fittings:

- Pressure Rating: The fitting should be able to withstand the hydraulic system’s maximum pressure.

- Temperature Rating: The hydraulic fluid’s temperature range should match the fitting’s working range.

- Corrosion Resistance: The material of the fitting should be resistant to corrosion from the environment and hydraulic fluid.

- Vibration Resistance: The fitting should be shock and vibration resistant.

- Compatibility with Hydraulic Fluid: The hydraulic fluid used in the system and the material of the fitting should be compatible.

Hydraulic Fittings Installation and Maintenance

For hydraulic systems to be reliable and safe, they must be installed and maintained correctly. The following guidelines will guide you in installing and maintaining hydraulic fittings:

- Cleanliness: Ensure all parts are free of debris and clean before assembling.

- Proper Torque: Avoid damage and leaks by tightening fittings to the recommended pressure.

- Regular Inspection: Check fittings for leaks, damaged or worn out on a regular basis.

- Replacement: Replace worn-out or damaged fittings as soon as possible.

You can make sure your hydraulic systems operate at their best and last a long time by listening to these recommendations and choosing the right types of hydraulic fittings.

Additional Tips for Selecting Hydraulic Fittings:

- Consider the application: The selection of the fittings will depend on the type of hydraulic system and its specific needs.

- Consult with a hydraulic expert: If you’re still unsure which type of fitting best suits your application, you should consult with a hydraulic engineer or technician.

- Follow the manufacturer’s instructions: Installation and maintenance instructions always come from the manufacturer’s documentation.