Durable Brass Ferrule Fittings for Reliable Plumbing Solutions

May 12, 2024

Ferrule Pipe Fittings: A Simple Guide to Reference

August 22, 2024Introduction

Ferrule pipe fittings, often referred to as compression fittings, are essential components in countless industrial and commercial applications. These fittings play a pivotal role in ensuring the secure and leak-free connection of pipes and tubes, making them indispensable in fluid and gas handling systems. We will delve into the world of ferrule pipe fittings in this extensive tutorial, covering their types, construction, benefits, uses, and best practices for installation.

Understanding Ferrule Pipe Fittings

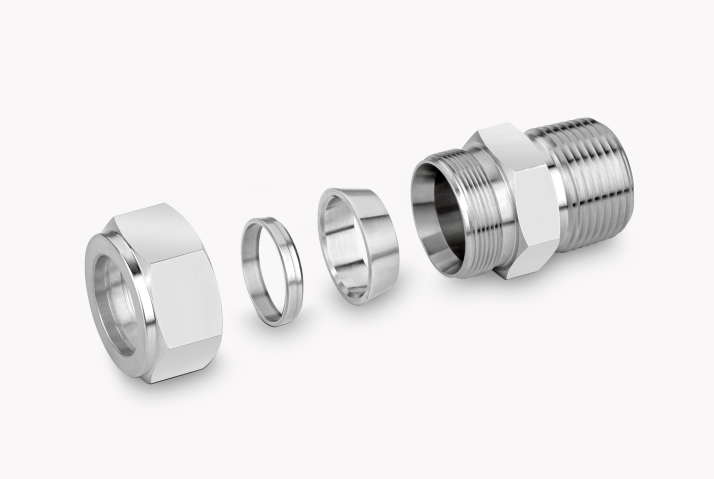

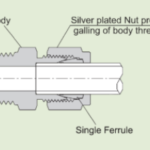

Ferrule pipe fittings consist of three primary components: the fitting body, a nut, and a ferrule. The ferrule, typically made of brass or copper, is a ring-shaped component that creates a seal when tightened. The nut, usually made of stainless steel, secures the ferrule and tube in place.

Types of Ferrule Pipe Fittings

Ferrule pipe fittings are available in various types to suit different applications and pipe materials. The most common types include:

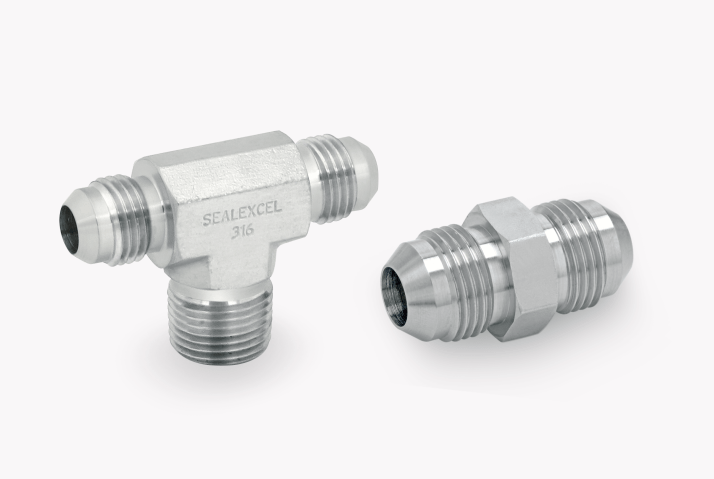

- Straight connectors: Used to connect two pipes in a straight line.

- Elbows: used to reverse a pipe’s direction.

- Tees: Used to create a branch in a pipe.

- Couplings: Used to connect two pipes of the same size.

- Reducers: used to join pipes with varying diameters.

Advantages of Ferrule Pipe Fittings

Ferrule pipe fittings offer several advantages over other types of pipe fittings:

- Easy installation: Installing ferrule fittings is not too difficult and doesn’t require any specialized equipment.

- Reusability: The fittings can be reused multiple times if the ferrule is in good condition.

- Leak-proof seals: When properly installed, ferrule fittings create reliable and leak-proof seals.

- Versatility: Ferrule fittings are available in a wide range of sizes and materials to suit various applications.

- Cost-effective: Compared to other types of fittings, ferrule fittings are generally more cost-effective.

Applications of Ferrule Pipe Fittings

Ferrule pipe fittings find extensive applications across diverse industries, including:

- Chemical processing: Handling corrosive and hazardous chemicals requires reliable connections.

- Pharmaceutical manufacturing: Maintaining hygienic conditions is crucial in pharmaceutical production.

- Food and beverage processing: Preventing contamination is essential in the food and beverage industry.

- Oil and gas: Ferrule fittings are used in various components of oil and gas pipelines.

- HVAC systems: Reliable connections are vital for efficient heating and cooling systems.

- Instrumentation and control: Accurate measurements and control depend on secure connections.

Choosing the Right Ferrule Pipe Fittings

Selecting the appropriate ferrule pipe fittings involves considering several factors:

- Pipe material: The type of pipe material will determine the suitable ferrule and fitting material.

- Fluid or gas type: The properties of the fluid or gas will influence the choice of fittings.

- Pressure and temperature ratings: The fittings must be rated for the operating conditions.

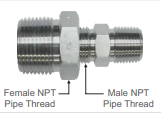

- End connection type: The type of end connection (e.g., tube, pipe) will dictate the fitting style.

Installation of Ferrule Pipe Fittings

Proper installation is crucial for ensuring the reliability and longevity of ferrule pipe fittings. Follow these general guidelines:

- Prepare the pipe: Cut the pipe to the desired length and deburr the cut end.

- Insert the ferrule: Slide the ferrule onto the pipe.

- Assemble the fitting: Insert the pipe into the fitting body.

- Tighten the nut: Tighten the nut using a wrench, ensuring proper torque.

- Check for leaks: After installation, inspect for leaks.

Maintenance and Troubleshooting

Regular inspection and maintenance are essential for the continued performance of ferrule pipe fittings. Check for leaks, wear, or damage. If any issues arise, tighten the nut slightly or replace the ferrule if necessary.

Conclusion

Ferrule pipe fittings are versatile and reliable components that play a critical role in various industries. Their ease of installation, reusability, and leak-proof seals make them a preferred choice for many applications. By understanding the different types of ferrule fittings, their advantages, and proper installation techniques, you can ensure the efficient and safe operation of your fluid or gas handling systems.