Ball Valves and Its Role In The Food & Beverage Industry

August 27, 2016Keep Specifications In Mind When Cleaning Or Repairing Industrial Valves

August 31, 2016As the industrial sector gets more competitive by the day, the need for strong and durable valves has

According to the latest design trends, a number of them promise more than 50% higher flow rate and a longer operational life. In addition, new designs also offer a wider temperature range and pressure handling capabilities that can enhance the performance of industrial processes exponentially.

The following are some more recent trends that are revolutionizing the industrial valve sector:

Ceramic and Quarter Turn Valves

Ceramic and Quarter Turn Valves

Ceramic valves are being produced which have strong sealing components and wearing parts that are made from the same material. This material does not corrode and can resist abrasions for years thus resulting in an extremely efficient pressurized system.

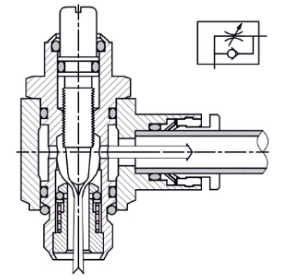

There has been an increase in demand for quarter turn valves which need to be rotated 90 degrees. Some of the main ones include butterfly, plug as well as ball valves which are known for improving water resistance and provide protection against corrosion as well.

Besides improving performance, this also extends the operational life of the valves because they contain closure shafts which can be used to quickly open and close them.

The growth of the water industry has increased this demand since these are designed specifically to

Besides ceramic and quarter turn valves, some companies are also tapping into technology to create valves that are truly innovative in design and function. It might not be long before we see some that can be activities via wireless communication technology.

At SEALEXCEL, we use only high end and state of the art equipment to manufacture and maintain our valves. We also keep up with the latest trends in the market to keep our clients competitive in their respective fields. Our stainless steel valves offer high steam and fluid performance and are designed keeping precision in mind which makes their emission control much better than other valves. For more information on our products and how they can enhance your production cycles please do not hesitate to contact us by dialing 0091-22-26788534.