Why Stainless Steel 316L is the Gold Standard for Pneumatic Components

August 20, 2025

Water Filtration Systems in Mumbai: Choosing the Right Stainless Steel Connectors

August 24, 2025In industries like oil, chemical, and pharmaceuticals, operational continuity is critical. Downtime, whether caused by equipment failure or maintenance issues, can lead to significant financial losses and safety risks. One of the key solutions to minimizing interruptions is the use of threaded instrumentation fittings in Mumbai, designed to withstand extreme conditions. These fittings ensure secure connections and reliable performance, even under high pressure and temperature, making them indispensable in harsh industrial environments.

The Role of Threaded Instrumentation Fittings in Industrial Stability

Threaded instrumentation fittings serve as essential connectors in complex piping and instrumentation systems. Their primary purpose is to create a dependable seal between different components, preventing leaks that could cause process failures or safety hazards. In environments where chemicals, high pressures, or temperature fluctuations are prevalent, the integrity of these fittings becomes even more vital. Properly designed high-pressure fittings can withstand these stresses, maintaining operational stability and reducing downtime caused by leaks or component failures.

Advantages of Precision-Threaded Fittings for Harsh Conditions

Precision threading in instrumentation fittings ensures a tight, secure connection that resists loosening over time. This characteristic is especially important when working with food-grade stainless steel fittings or stainless steel air fittings, which require both durability and cleanliness. Suppliers of stainless steel fittings often emphasize the importance of high-quality threading to prevent system failures. Benefits include enhanced reliability, reduced maintenance costs, and a longer service life, all of which contribute to uninterrupted operations in demanding environments.

Material Selection: Why Stainless Steel Is the Material of Choice

Stainless steel, particularly grades 316 and 316L, is favored by pneumatic fittings manufacturers and other industrial fittings due to its corrosion resistance and strength. These properties are crucial for applications involving aggressive chemicals, high pressures, or extreme temperatures. The use of stainless steel hygienic fittings guarantees that systems remain clean and compliant with safety standards, especially in sectors like food processing and pharmaceuticals.

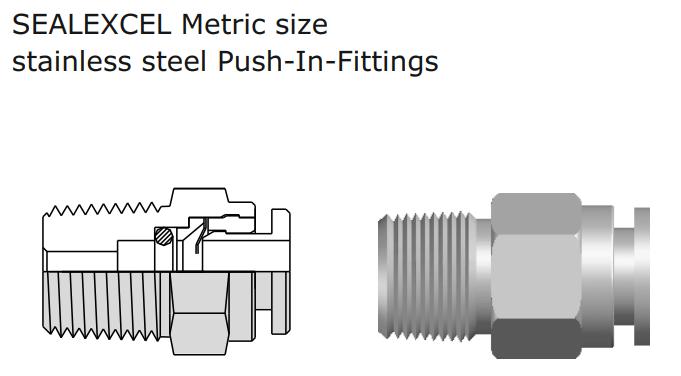

Innovations in Fitting Design for Easy Maintenance and Quick Assembly

Modern push-to-connect fittings and quick-connect fittings are designed for ease of installation and rapid maintenance. These fittings allow technicians to connect or disconnect lines swiftly, reducing system downtime during repairs or adjustments. Features such as push-in tube fittings are particularly valuable in environments requiring frequent cleaning or system reconfiguration.

Quick-connect fittings are easy to install

Commitment to Quality and Reliability in Fittings

Choosing the right pneumatic quick-connect couplings or industrial pneumatic connectors is essential for operational continuity. Manufacturers specializing in stainless steel fittings focus on delivering products that meet the highest standards, with many fittings NSF-approved to ensure durability and safety. Their extensive range of push-in fittings and food and beverage connectors provides tailored solutions for various industrial needs.

Experience the Difference with Precision Solutions

In the demanding world of industrial operations, downtime is costly. Seal Excel offers top-tier threaded instrumentation fittings in Mumbai designed for durability and reliability in extreme conditions. Our fittings are engineered to prevent failures, ensuring seamless performance in critical applications. To discuss your specific needs and explore how we can help, reach out to our team today. Discover how our solutions can keep your Mumbai operations running smoothly and efficiently.