Best Practices for Using Pneumatic Push-In Fittings

January 4, 2023

Common Mistakes to Avoid When Using Stainless Steel Pipe Fittings

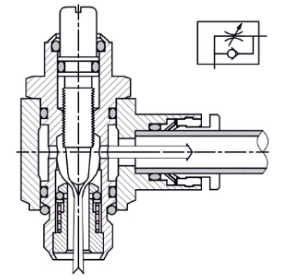

February 5, 2023The thing with a needle valve is that they are designed in such a way that they can regulate the flow to an instrument – they can also be used in general industrial applications as a shut-off mechanism. Needle valves are durable enough for them to be used abundantly in the oil and gas market. In fact, they are suitable for most industrial applications. They are available in a diverse array of connections and their bodies are made mostly from materials such as carbon steel and stainless steel. Needle valves play a major role in isolating and controlling flow.

Some More Things To Know About These Valves

Needle valves are used commonly for controlling the flow of materials with a lot of accuracies. When you turn the handle the tip or screw plug moves down or up thus regulating the flow of the material. The small threads on the stem and the tip have a conical shape and this allows for more control when you are using a needle valve. The control that these valves offer you is commendably higher than the likes of ball and globe valves. Needle valves are also used to regulate flow to instruments in various general industrial applications.

They can be used as shut-off mechanisms as well.

What Are Ball Valves?

Ball valves are normally used to totally shut off the flow of materials. When you use them as a pressure gauge with ball valve their main role is to isolate a part of the process. Compared to the needle valves they allow for a much higher flow rate. This is because when such a valve is completely open there is no extra flow restriction.

What Are Gauge Cocks?

Gauge cocks are used for shutting off the flow of media to pressure instruments, which is useful for replacing a pressure instrument or inspecting one.

What Are Pressure Gauge Pigtails?

When it comes to pressure gauges in steam systems, these are the most important parts of the same. It is common knowledge that steam is hot, it condenses, and if we attempt to pass it through a condensate it would flash and lead to a hammer. If it gets in the bourdon tube of a gauge the condensate would not be able to drain as it would sit in the lower part of the tube. So, the next time you try passing steam through the gauge it would be destroyed. A pigtail can protect the gauge by forming a condensate trap.

What Are Pressure Gauge Isolation Valves?

A pressure gauge isolation valve is supposed to save the pressure gauges. The best options in these cases are needle valves rather than ball valves. They may take 15 more seconds to open than the latter, but this is something that you must accept considering the extra protection that they offer. A shut-off valve can be the most mundane industrial equipment. In most cases, they are fitted with isolation quarter turn ball valves that can compromise the accuracy of pressure gauges, which is a common complaint in these cases.

Conclusion

Last, but definitely not least, on this list is pressure gauge snubbers. They are supposed to dampen or retard pulsations at the gauge. When it comes to gauges in closed systems it is common to see them with bouncing needles because either the pump is vibrating or there is air in the system. Well, if you have these problems already you can be sure that you would have to deal with more than the simple movement of a pressure gauge as such issues can damage other equipment over there as well.