Hydraulic Fittings & Connectors: Sealing the Deal

June 4, 2024

Different Type of Hydraulic Connectors. An Overview

November 15, 2024Important components of hydraulic systems are hydraulic fittings. They are used to connect and disconnect pipes and hydraulic hoses. The types and sizes of hydraulic fitting are numerous.

What are the benefits of using quality hydraulic fittings?

The following advantages come with using premium hydraulic fittings:

- Enhanced system efficiency: By utilising premium hydraulic fitting, you can make your hydraulic system more efficient. This is because high-quality fittings are less likely to leak, which could cause your system to lose pressure.

- Increased reliability: hydraulic fittings of superior quality are safer than those of inferior quality. This is because they are made with superior materials and to higher standards.

- Improved safety: Compared to less expensive hydraulic fittings, the best ones are safer to use. This is due to the fact that they are less likely to have leaks, which could cause injuries when hydraulic fluid pours out.

- Reduced maintenance costs: You can save money on maintenance by investing in high-quality hydraulic fitting. This is because they are less likely to need to be replaced.

- Reduced downtime: Good hydraulic fittings can let you spend less time offline. Leakage is less likely to occur, which could cause issues for your system.

Types of hydraulic connections

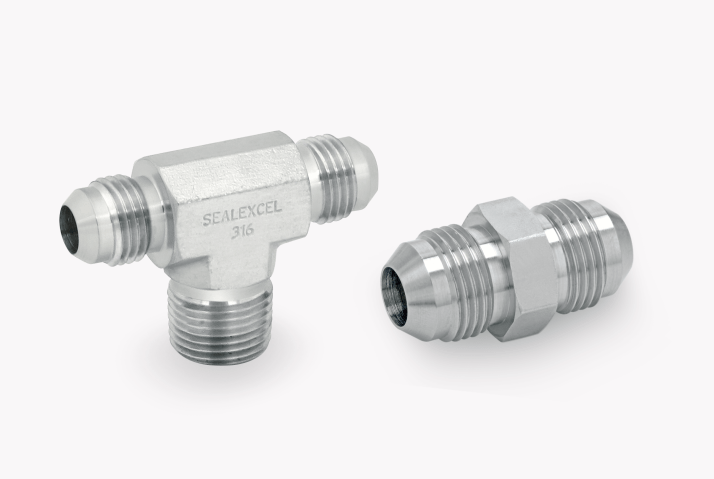

There are several types of hydraulic fittings. The most typical ones are:

- Straight fittings: Straight connectors are used to join two hydraulic hoses or pipes in a straight line.

- Elbow fittings: Elbow connectors are used to join two hydraulic hoses or pipes at a 90-degree angle.

- Tee fittings: Tee connections are used to join three hydraulic hoses or pipes.

- Cross fittings: Cross fittings are used to join four hydraulic hoses or pipes.

- Swivel fittings: Swivel fittings allow a hydraulic pipe or hose to turn.

- Reducing fittings: These are used to connect two hydraulic hoses or pipes of various sizes.

Tips for selecting the best hydraulic fittings

When choosing hydraulic fittings, the following factors should be considered:

- The type of hydraulic system: The sort of hydraulic system will impact the type of hydraulic fitting needed.

- The working pressure of the hydraulic system: The hydraulic system’s working pressure will dictate the operating pressure of the hydraulic fitting.

- The type of hydraulic fluid: The type of hydraulic fluid will determine the materials needed to build the hydraulic fitting.

- The size of the hydraulic hoses or pipes: The size of the hydraulic hoses or pipes will determine the dimensions of the hydraulic fittings.

How to keep hydraulic connections maintained

Hydraulic fittings require minimal care. However, it’s important to regularly inspect them for damage. The replacement of a damaged hydraulic fitting is necessary.

Conclusion

Using high-quality hydraulic fitting has several benefits, including increased safety, decreased maintenance costs, improved security, increased system efficiency, and decreased interruptions. When choosing hydraulic fitting, it is important to consider the type of hydraulic system, its working pressure, the type of hydraulic fluid, and the size of the hydraulic hoses or pipes.