INSTALLATION INSTRUCTIONS

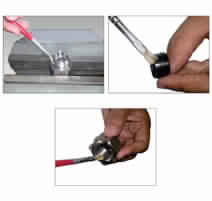

ASSEMBLY IN HARDENED PRE-ASSEMBLY BODY.

1

In order to ensure positive assembly, SEALEXCEL recommend pre-assembled the tube and fittings in hardened pre-assembly Body.

2

Ensure that the end of Tube is cut square within + 1/2º angle to the tube axis.

Remove the burs and sharp edges to the maximum chamfer 0.2 mm x 45º at both inside and outside edge of the tube.

Remove the burs and sharp edges to the maximum chamfer 0.2 mm x 45º at both inside and outside edge of the tube.

3

Lubricate the thread and cone of the pre-assembly body, Bite Ring and thread of the nut.

4

Insert the Nut and Bite Ring over tube end.

5

Screw on Nut manually on to pre-assembly body until finger tight, hold tube against the shoulder in the cone of pre-assembly body

6

Tighten the Nut with wrench 1 turn from the finger tight position.

7

Loosen the Nut, remove the tube from the pre-assembly body, check the penetration of cutting edge. A visible collar fills space in front of first cutting edge completely. It does not matter even Bite Ring rotate on tube end.

8

Final assembly in Fitting body Put pre-installed tube in to the fitting body.

Tighten the Nut with wrench by approx 1/2 turns beyond point of clearly perceptible resistance

9

Repeated Assembly

Each time the fitting is disassembled, the nut must be re-tightened firmly using the same torque as required for final assembly

Each time the fitting is disassembled, the nut must be re-tightened firmly using the same torque as required for final assembly