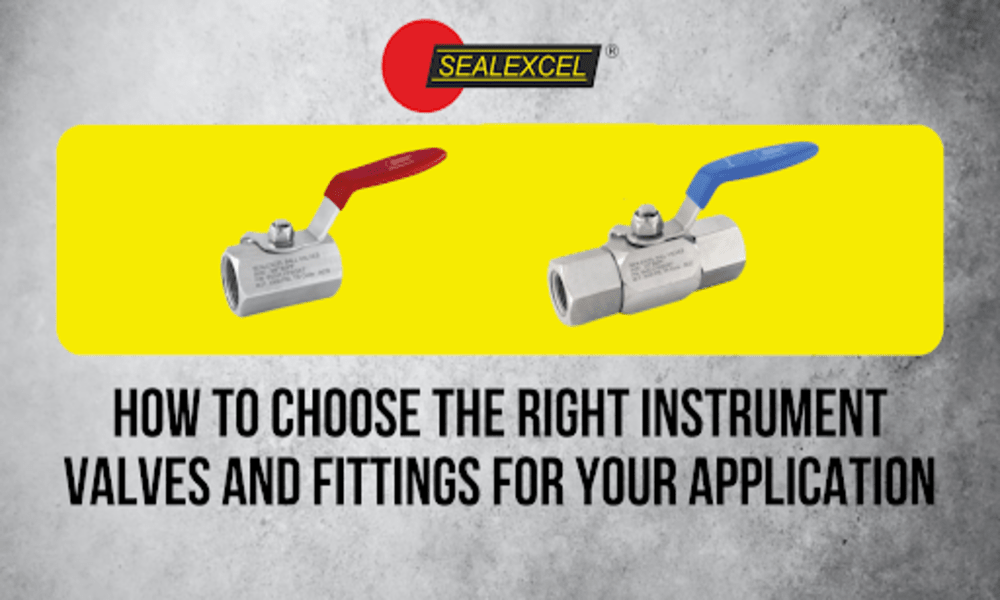

How to Choose the Right Instrument Valves and Fittings for Your Application

January 4, 2023

Manifold Valves in Action: Case Studies Across Diverse Industries

February 6, 2024In the intricate web of industrial machinery, Instrumentation Fittings stand as unsung heroes, ensuring seamless connections and precision in various applications. These fittings might seem inconspicuous, but their role in facilitating fluid and gas handling within industrial systems is pivotal. Let’s delve into their significance, types, applications, and best practices.

Understanding Instrumentation Fittings:

Instrumentation fittings are specialized components designed to connect and seal tubing or piping systems used in industrial instrumentation and process control applications. They play a crucial role in maintaining leak-free connections, ensuring accuracy in pressure and flow measurements, and enabling smooth operation within diverse industrial setups.

Types of Instrumentation Fittings:

These fittings come in various types, each tailored to specific needs. Compression fittings, tube fittings, flare fittings, and pipe fittings are among the common types. Their designs cater to different pressure ratings, environmental conditions, and connection methods, allowing for versatility in industrial applications.

Applications Across Industries:

Instrumentation Fittings find use across a wide spectrum of industries, from oil and gas to pharmaceuticals, food processing, and beyond. In the oil and gas sector, these fittings facilitate the safe and precise transmission of fluids and gases in pipelines and refineries. In laboratories, they ensure accurate flow and pressure in analytical instruments.

Ensuring Precision and Reliability:

Precision is paramount in industrial processes, and instrumentation fittings play a crucial role in achieving this. They enable tight seals, preventing leaks that could compromise accuracy and efficiency. The reliability of these fittings under high pressures and varying temperatures ensures the consistent performance of industrial systems.

Factors Influencing Selection:

Choosing the right instrumentation fitting involves considering various factors. Compatibility with the fluid or gas being transported, pressure and temperature ratings, material composition, and environmental conditions are crucial aspects. This ensures optimal performance and longevity of the fittings within specific applications.

Installation and Maintenance Best Practices:

Proper installation and maintenance are essential for maximizing the lifespan and efficiency of instrumentation fittings. Correct assembly techniques, ensuring proper torque, regular inspections, and replacing worn-out components are vital steps in ensuring their functionality and safety.

Advancements and Innovations:

Continual advancements in materials and designs contribute to the evolution of instrumentation fittings. Manufacturers strive to develop fittings that offer improved performance, better resistance to corrosion, higher pressure tolerances, and ease of installation to meet the ever-evolving industrial demands.

Conclusion:

Instrumentation fittings might be small components, but their impact on industrial applications is immense. Their role in maintaining precision, reliability, and safety within fluid and gas handling systems is undeniable. Understanding their types, applications, proper selection criteria, and maintenance practices is crucial for optimizing their performance and ensuring seamless operations in diverse industrial settings.