Stainless Steel Needle Valves

FEATURES

- Available in SS316, all wetted parts in accordance with NACE MR01-75

- Heat Code Traceable to certified material test report

- Low operating torques

- Bar stock Body in Straight Patterns

- Anti Blow-out stem, Variety of stem tips

- PTFE packing standard

- Flow coefficient (Cv) From 0.35 to 1.8

- Orifice size : 0.156" (4.0 mm), 0.250" (6.4mm), 0.375" (9.5mm)

- Variety of end configuration includes SEALEXCEL® Well-Lok™ Tube Fittings, Male / Female NPT, BSPT, BSPP pipe and tube socket weld connections

- Every valve is factory tested.

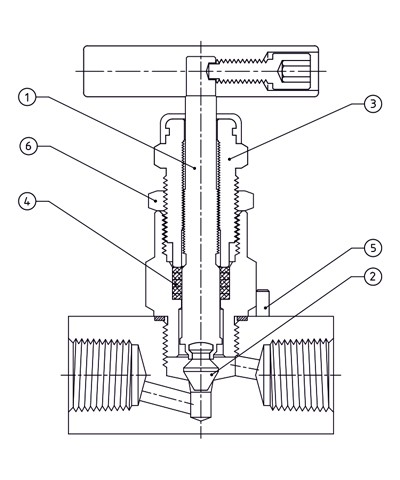

| No. | Description | Features and Benefits |

| 1. | Anti Blow-out Stem | i) Rolled and plated stem threads for excellent Stem performance & extended service life. II) Non Rotating self centering stem tip for superior & repeatable perfect sealing. III) Burnished stem at packing area to ensure low torque operation of the valve & reduction in packing wear. |

| 2. | Stem Tip | Burnished to achieve high grade surface finish and work hardness for excellence performance and extended service life |

| 3. | Packing Bolt | Allows packing adjustment in open or close position. |

| 4. | Packing | Packing below the threads protects the flow stream from lubricant contamination on the threads or wash out and also protect the stem threads from potential damaging effects of the media. |

| 5. | Locking Pin | To prevent accidental loosening / disassembly of valve. |

| 6. | Bonnet Lock Nut | For safety to prevent accidental loosening of packing bolt |

OPERATING PARAMETERS

- Pressure Rating : upto 6000 psig (408 bar) at CWP

- Temperature Rating :

- -54ºC to 232ºC with standard PTFE packing

- upto 426ºC with optional Graphite packing

APPLICATIONS

- General Plant Service

- Instrument Isolation

- Hydraulic and Pneumatic

- Pressure measurement devices

- Venting

MATERIAL OF CONSTRUCTIONS

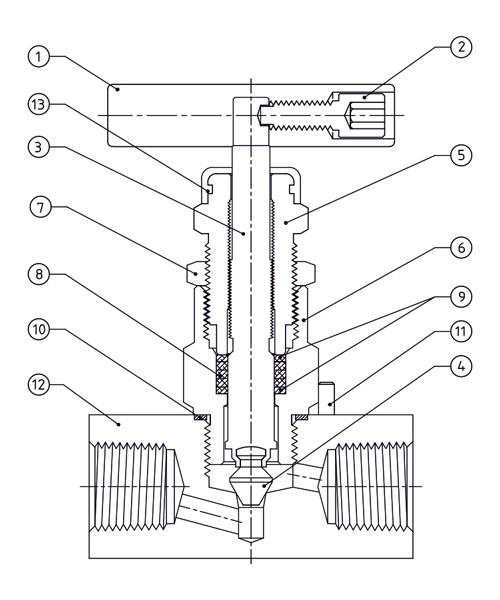

| Sr. No. | Part Description | Material |

| 1. | Bar Handle | SS316 |

| 2. | Screw | SS316 |

| 3. | Stem | SS316 |

| 4. | Stem Tip | SS316 |

| 5. | Packing Bolt | SS316 |

| 6. | Bonnet | SS316 |

| 7. | Bonnet Lock Nut | SS316 |

| 8. | Packing | PTFE |

| 9. | Packing Support | GFT |

| 10. | Washer | SS316 |

| 11. | Bonnet Safety Pin | SS316 |

| 12. | Valve Body | SS316 |

| 13. | Dust Cap | PVC |

STEM TYPE :

SEALEXCEL® Needle Valves are available with choice of optional stem to provide greater flexibility.

NON-ROTATING (NR) : It is Standard self centering non rotating stem tip typically used in high cycle application to extend the valve life.

V-STEM (VS) : It is used for general purpose liquid and gases.

SOFT SEAT (SS) : A soft seat stem requires a lower sealing torque, It is replaceable and suitable for temperature upto 120ºC

REGULATING STEM (RS) : It is used where some degree of flow control required.

TECHNICAL DATA

The Temperature and Pressure rating for a standard valve with PTFE packing

| Temperature | Pressure | |

| psig | bar | |

| -54ºC to 38ºC | 6000 | 408 |

| -54ºC to 93ºC | 5160 | 351 |

| -54ºC to 148ºC | 4660 | 317 |

| -54ºC to 204ºC | 4280 | 291 |

| -54ºC to 232ºC | 4130 | 289 |

TESTING :

- Standard Test : Each valve is factory tested with nitrogen at 1000 psig (69 bar) for leakage at the seat and packing.

- Optional Hydrostatic test : This test is performed with de-ionised water at 1.5 time the working pressure.

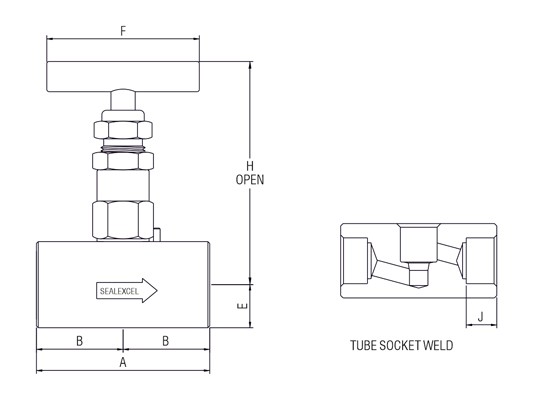

TABLE OF DIMENSIONS

| End Connections | Orifice | Cv | Dimensions (mm) | Ordering Number | ||||||

| Inlet | Outlet | A | B | E | F | H Straight | J | |||

| 1/4" Well-Lok | 1/4" Well-Lok | 4.0 | 0.35 | 62.0 | 31.0 | 12.7 | 52.5 | 73.0 | - | BS03-TT4 |

| 3/8" Well-Lok | 3/8" Well-Lok | 6.4 | 0.86 | 73.0 | 36.5 | 14.3 | 63.5 | 88.0 | - | BS03-TT6 |

| 1/2" Well-Lok | 1/2" Well-Lok | 6.4 | 0.86 | 77.8 | 38.9 | 14.3 | 63.5 | 88.0 | - | BS03-TT8 |

| 3/4" Well-Lok | 3/4" Well-Lok | 11.0 | 2.2 | 100.0 | 50.0 | 15.9 | 69.9 | 114.0 | - | BS03-TT12 |

| 6mm Well-Lok | 6mm Well-Lok | 4.0 | 0.35 | 62.0 | 31.0 | 12.7 | 52.5 | 73.0 | - | BS03-TT6M |

| 8mm Well-Lok | 8mm Well-Lok | 4.0 | 0.35 | 62.0 | 31.0 | 12.7 | 52.5 | 73.0 | - | BS03-TT8M |

| 10mm Well-Lok | 10mm Well-Lok | 6.4 | 0.86 | 73.0 | 36.5 | 14.3 | 63.5 | 88.0 | - | BS03-TT10M |

| 12mm Well-Lok | 12mm Well-Lok | 6.4 | 0.86 | 77.8 | 38.9 | 14.3 | 63.5 | 88.0 | - | BS03-TT12M |

| 1/8" Female NPT | 1/8" Female NPT | 4.0 | 0.35 | 50.8 | 25.4 | 12.7 | 47.6 | 73.0 | - | BS03-FF2N |

| 1/4" Female NPT | 1/4" Female NPT | 4.0 | 0.35 | 57.2 | 28.6 | 12.7 | 52.5 | 73.0 | - | BS03-FF4N |

| 3/8" Female NPT | 3/8" Female NPT | 6.4 | 0.86 | 60.4 | 30.2 | 14.3 | 63.5 | 88.0 | - | BS03-FF6N |

| 1/2" Female NPT | 1/2" Female NPT | 11.0 | 2.2 | 79.4 | 39.7 | 15.9 | 69.9 | 113.0 | - | BS03-FF8N |

| 3/4" Female NPT | 3/4" Female NPT | 11.0 | 2.2 | 79.4 | 39.7 | 17.5 | 69.9 | 115.0 | - | BS03-FF12N |

| 1" Female NPT | 1" Female NPT | 11.0 | 2.2 | 92.0 | 46.0 | 22.5 | 69.9 | 122.0 | - | BS03-FF16N |

| 1/4" Male NPT | 1/4" Male NPT | 4.0 | 0.35 | 57.2 | 28.6 | 12.7 | 52.5 | 73.0 | - | BS03-MM4N |

| 1/4" Male NPT | 1/4" Female NPT | 4.0 | 0.35 | 57.2 | 28.6 | 12.7 | 52.5 | 73.0 | - | BS03-MF4N |

| 1/2"Male NPT | 1/2" Female NPT | 11.0 | 2.2 | 79.4 | 39.7 | 15.9 | 69.9 | 113.0 | - | BS03-MF8N |

| 3/4" Male NPT | 3/4" Female NPT | 11.0 | 2.2 | 79.4 | 39.7 | 17.5 | 69.9 | 115.0 | - | BS03-MF12N |

| 1" Male NPT | 1" Female NPT | 11.0 | 2.2 | 92.0 | 46.0 | 22.5 | 69.9 | 122.0 | - | BS03-MF16N |

| 1/4 " TSW | 1/4 " TSW | 4.0 | 0.35 | 46.0 | 23.0 | 12.7 | 52.5 | 73.0 | 7.2 | BS03-TSW4 |

| 3/8" TSW | 3/8" TSW | 6.4 | 0.86 | 57.2 | 28.6 | 14.3 | 63.5 | 88.0 | 8.0 | BS03-TSW6 |

| 1/2" TSW | 1/2" TSW | 6.4 | 0.86 | 57.2 | 28.6 | 14.3 | 63.5 | 88.0 | 9.6- | BS03-TSW8 |

| 3/4" TSW | 3/4" TSW | 11.0 | 2.2 | 79.4 | 39.7 | 15.9 | 69.9 | 113.0 | 11.1 | BS03-TSW12 |

Dimensions shown with SEALEXCEL® Well-Lok™ Nut are finger tight

Dimensions are for reference only and subject to change without notice

FAQs

What is a needle valve used for?

A needle valve is used to regulate the flow of a substance. The flow can be either gas or water through an application or a system. Seal Excel is one of the best needle valves manufacturers in India. We have an extensive range of Needle valves.

How do you use a needle valve?

The needle valve can be operated automatically or manually. For manual use, one requires a handwheel to control the distance between plunger and valve. Seal Excel is the finest needle valve manufacturer. We bring to you a thoughtful range of quality needle valves.

Do needle valves reduce pressure?

No, the needle valve does not reduce the pressure; they control the flow and protect the gauges. It removes the chances of potential damages caused due to a sudden surge in pressure.

How do you install a needle valve?

The handle of the needle valve is connected to the plunger. When you turn the handle of the valve the plunger moves up or down depending upon the threads. As the plunger moves down the tapered point end comes in contact with the valve and fully seals it.

Stainless Steel Needle Valves