Needle Valves : Series - BS05

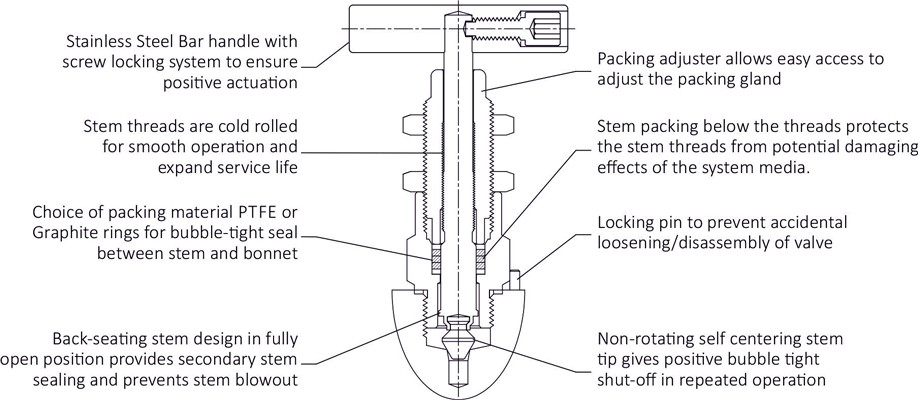

FEATURES

- Available in material SS316, Inconel, Monel, Duplex etc. all wetted parts in accordance with NACE MR01-75

- Heat Code Traceable to certified material test report

- Bar Stock Body Straight pattern, Panel Mountable

- Variety of end configurations includes SEALEXCEL® Well-Lok™ Tube Fittings, Male/Female NPT, BSPT, BSPP pipe and tube socket weld connections

- Flow coefficients (Cv) from 0.35 to 2.2

- Orifice size : 0.156" (4mm), 0.250" (6.4mm) and 0.437" (11mm)

- Every valve is factory tested.

OPERATING PARAMETERS

- Pressure Rating : upto 6000 psig (413 bar) at CWP

- Temperature Rating :

- -54ºC to 232ºC with standard PTFE packing

- upto 426ºC with optional Graphite packing

APPLICATION

- General Plant Service

- Instrument Isolation

- Hydraulic and Pneumatic

- Pressure measurement devices

- Venting

STEM TYPE

SEALEXCEL Needle Valves are available with a choice of the optional stem to provide greater flexibility.

MATERIAL OF CONSTRUCTIONS

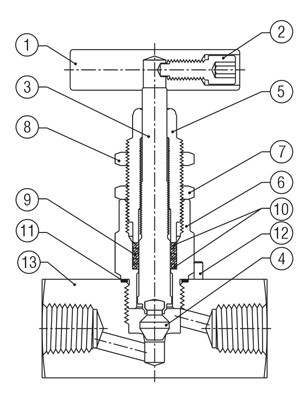

| Sr. No. | Part Description | Material |

| 1. | Bar Handle | SS316 |

| 2. | Set Screw | SS316 |

| 3. | Stem | SS316 |

| 4. | Stem Tip | SS316 |

| 5. | Packing Adjuster | SS316 |

| 6. | Bonnet | SS316 |

| 7. | Lock Nut | SS316 |

| 8. | Panel Nut | SS316 |

| 9. | Packing | PTFE/Graphite |

| 10. | Packing Washer | SS316 |

| 11. | Washer | SS316 |

| 12. | Bonnet Lock Pin | SS316 |

| 13. | Valve Body | SS316 |

TECHNICAL DATA

The Temperature and Pressure rating for a standard valve with PTFE packing.

| Temperature | Pressure | |

| psig | bar | |

| -54ºC to 38ºC | 6000 | 413 |

| -54ºC to 93ºC | 5160 | 351 |

| -54ºC to 148ºC | 4660 | 317 |

| -54ºC to 204ºC | 4280 | 291 |

| -54ºC to 232ºC | 4130 | 289 |

TESTING

- Standard Test: Each Valve is factory tested with nitrogen at 1000 psig(69 bar) for leakage at the seat, the maximum allowable leak rate of 0.1 sccm

- Optional Hydrostatic test : This test is performed with de-ionised water at 1.5 time the working pressure.

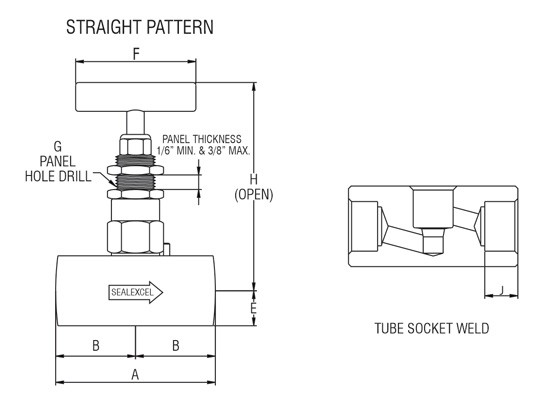

STANDARD CONFIGURATION DIMENSIONS

| End Connections | Orifice | Cv | Dimensions (mm) | Ordering Number | |||||||

| Inlet | Outlet | A | B | E | F | G | H | J | |||

| 1/4" Well-Lok | 1/4" Well-Lok | 4.3 | 0.37 | 73.0 | 36.5 | 12.7 | 52.5 | 15.1 | 77.8 | - | BS05-TT4 |

| 3/8" Well-Lok | 3/8" Well-Lok | 6.4 | 0.86 | 73.0 | 36.5 | 14.3 | 57.0 | 19.9 | 93.7 | - | BS05-TT6 |

| 1/2" Well-Lok | 1/2" Well-Lok | 6.4 | 0.86 | 77.8 | 38.9 | 14.3 | 57.0 | 19.9 | 93.7 | - | BS05-TT8 |

| 3/4" Well-Lok | 3/4" Well-Lok | 9.5 | 1.8 | 85.2 | 42.6 | 15.9 | 63.5 | 26.2 | 121.5 | - | BS05-TT12 |

| 6mm Well-Lok | 6mm Well-Lok | 4.3 | 0.37 | 73.0 | 36.5 | 12.7 | 52.5 | 15.1 | 77.8 | - | BS05-TT6M |

| 8mm Well-Lok | 8mm Well-Lok | 4.3 | 0.37 | 73.0 | 36.5 | 12.7 | 52.5 | 15.1 | 77.8 | - | BS05-TT8M |

| 10mm Well-Lok | 10mm Well-Lok | 6.4 | 0.86 | 73.0 | 36.5 | 14.3 | 57.0 | 19.9 | 93.7 | - | BS05-TT10M |

| 12mm Well-Lok | 12mm Well-Lok | 6.4 | 0.86 | 77.8 | 38.9 | 14.3 | 57.0 | 19.9 | 93.7 | - | BS05-TT12M |

| 1/8" Female NPT | 1/8" Female NPT | 4.3 | 0.37 | 57.2 | 28.6 | 12.7 | 52.5 | 15.1 | 77.8 | - | BS05-FF2N |

| 1/4" Female NPT | 1/4" Female NPT | 4.3 | 0.37 | 57.2 | 28.6 | 12.7 | 52.5 | 15.1 | 77.8 | - | BS05-FF4N |

| 3/8" Female NPT | 3/8" Female NPT | 6.4 | 0.86 | 60.4 | 30.2 | 14.3 | 57.0 | 19.9 | 93.7 | - | BS05-FF6N |

| 1/2" Female NPT | 1/2" Female NPT | 6.4 | 0.86 | 66.6 | 33.3 | 15.9 | 57.0 | 26.2 | 121.5 | - | BS05-FF8N |

| 3/4" Female NPT | 3/4" Female NPT | 9.5 | 1.8 | 69.8 | 34.9 | 17.5 | 63.5 | 26.2 | 123.9 | - | BS05-FF12N |

| 1" Female NPT | 1" Female NPT | 9.5 | 1.8 | 92.0 | 39.6 | 22.5 | 63.5 | 26.2 | 129.4 | - | BS05-FF16N |

| 1/4" Male NPT | 1/4" Male NPT | 4.3 | 0.37 | 57.2 | 28.6 | 12.7 | 52.5 | 15.1 | 77.8 | - | BS05-MM4N |

| 1/4" Male NPT | 1/4" Female NPT | 4.3 | 0.37 | 57.2 | 28.6 | 12.7 | 52.5 | 15.1 | 77.8 | - | BS05-MF4N |

| 1/2"Male NPT | 1/2" Female NPT | 6.4 | 8.6 | 69.8 | 34.9 | 15.9 | 57.0 | 26.2 | 121.5 | - | BS05-MF8N |

| 3/4" Male NPT | 3/4" Female NPT | 9.5 | 1.8 | 82.6 | 41.3 | 17.5 | 63.5 | 26.2 | 123.9 | - | BS05-MF12N |

| 1" Male NPT | 1" Female NPT | 9.5 | 1.8 | 85.8 | 42.9 | 22.5 | 63.5 | 26.2 | 129.4 | - | BS05-MF16N |

| 1/4 " TSW | 1/4 " TSW | 4.3 | 0.37 | 57.2 | 28.6 | 12.7 | 52.5 | 15.1 | 77.8 | 7.2 | BS05-TSW4 |

| 3/8" TSW | 3/8" TSW | 6.4 | 0.86 | 57.2 | 28.6 | 14.3 | 57.0 | 19.9 | 93.7 | 8.0 | BS05-TSW6 |

| 1/2" TSW | 1/2" TSW | 6.4 | 0.86 | 66.6 | 33.3 | 14.3 | 57.0 | 19.9 | 93.7 | 9.6 | BS05-TSW8 |

| 3/4" TSW | 3/4" TSW | 9.5 | 1.8 | 69.8 | 34.9 | 15.9 | 63.5 | 26.2 | 121.5 | 11.1 | BS05-TSW12 |

Dimensions shown with SEALEXCEL® Well-Lok™ Nut are finger tight

Dimensions are for reference only and are subject to change.

SEALEXCEL is amongst India’s largest needle valve manufacturers that cater to a global clientele from all over the world including Europe, Australia, Middle East and USA. We offer one of the most extensive range of needle valve in stainless steel that are designed and created after in-depth research so that we offer you defect free range of special purpose valves. We are expert in our filed and have been manufacturing and supplying valves and fittings for the last two decades and our range of needle valves include: industrial glove valves, butterfly valves, safety relief valves, industrial strainers and industrial valves.

Moreover all our needle valves undergo strict quality assurance procedures approved to ISO 9001:2015, PED 97/23/EC and ATEX 94/9/EC that help us in producing needle valves that are cost effective, low maintenance, corrosion resistance, easily installable and highly durable. All our valves have to undergo helium leak detection and Hydrostatics Burst pressure test so that we can guarantee maximum safety and reliability of our products in deep vacuum and high pressure applications. We also ensure that all our product deliveries are completed and done within the specified time and that all our products are provided to the customers according to requisite norms and standards.

Visit our site today and send us an enquiry – we promise you will not be disappointed because we believe that our customers are our true partners and their satisfaction is ultimate goal