Needle Valves : Series - BS31

FEATURES

- Available in SS316, all wetted par ts in accordance with NACE MR01-75

- Heat Code Traceable to certified material test report

- Bar Stock Body Straight patterns, Panel mountable

- Thread for greater strength and smoother operation

- Prevents lubricant washout

- Variety of end configurations includes SEALEXCEL® Well-Lok™ Tube Fittings Male/Female NPT, BSPT, BSPP pipe and tube socket weld connections

- Hardened Stem Tip

- Flow coefficients (Cv) from 0.35 to 0.86

- Orifice size : 0.156" (4mm) and 0.250" (6.4mm)

- Every valve is factory tested.

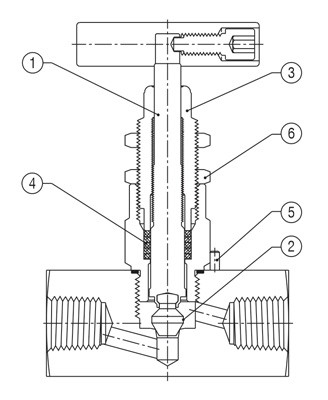

| No. | Description | Features and Benefits |

| 1. | Anti Blow-out Stem | i) Rolled and plated stem threads for excellent performance & extended service life. II) Non Rotating self centering stem tip for superior &repeatable perfect sealing. III) Burnished stem at packing area to ensure low torque operation of the valve & reduction in packing wear. |

| 2. | Stem Tip | Hardened Stem Tip for Excellence performance and Extended service life. |

| 3. | Packing Bolt | Allows packing adjustment in open or close position. |

| 4. | Packing | Packing below the threads protects the flow stream from lubricant contamination on the threads or wash out and also protect the stem threads from potential damaging effects of the media. |

| 5. | Locking Pin | To prevent accidental loosening / disassembly of valve. |

| 6. | Bonnet Lock Nut | For safety to prevent accidental loosening of packing bolt |

OPERATING PARAMETERS

- Pressure Rating : Upto 10,000 psig (680 bar) at CWP

- Temperature Rating :

- -54ºC to 232ºC with standard PTFE packing

- upto 426ºC with optional Graphite packing

APPLICATION

- General Plant Service

- Instrument Isolation

- Hydraulic and Pneumatic

- Pressure measurement devices

- Venting

STEM TYPE

SEALEXCEL Needle Valves are available with a choice of the optional stem to provide greater flexibility.

MATERIAL OF CONSTRUCTIONS

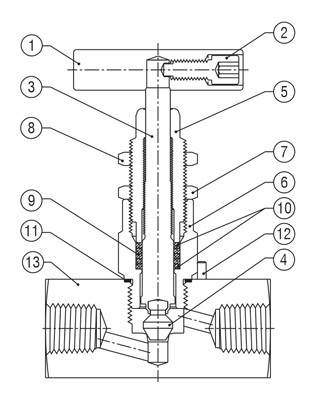

| Sr.NNoo. . | Part Description | Material |

| 1. | Bar Handle | SS316 |

| 2. | Set Screw | SS316 |

| 3. | Stem | SS316 |

| 4. | Stem Tip | Hardened - 17-4PH |

| 5. | Packing Bolt | SS316 |

| 6. | Lower Bonnet | SS316 |

| 7. | Lock Nut | SS316 |

| 8. | Panel Nut | SS316 |

| 9. | Packing | PTFE/Graphite |

| 10. | Back-up Ring | GFT |

| 11. | Washer | SS316 |

| 12. | Bonnet Lock Pin | SS316 |

| 13. | Valve Body | SS316 |

TECHNICAL DATA

The Temperature and Pressure rating for a standard valve with PTFE packing| Temperature | Pressure | |

| psig | bar | |

| -50ºC to 38ºC | 10,000 | 680 |

| -50ºC to 90ºC | 9290 | 632 |

| -50ºC to 145ºC | 8390 | 570 |

| -50ºC to 200ºC | 7705 | 524 |

| -50OC to 230ºC | 7435 | 505 |

TESTING

- Standard Test: Each Valve is factory tested with nitrogen at 1000 psig(69 bar) for leakage at the seat, the maximum allowable leak rate of 0.1 sccm

- Optional Hydrostatic test : This test is performed with de-ionised water at 1.5 time the working pressure.

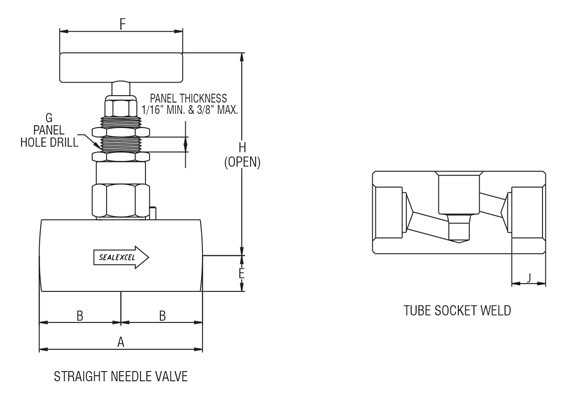

STANDARD CONFIGURATION DIMENSIONS

| End Connections | Orifice | Cv | Dimensions (mm) | Ordering Number | |||||||

| Inlet | Outlet | A | B | E | F | G | H (Open) | J | |||

| 1/8" Female NPT | 1/8" Female NPT | 4.0 | 0.35 | 57.2 | 28.6 | 12.7 | 52.5 | 19.8 | 82.8 | - | BS31-FF2N |

| 1/4" Female NPT | 1/4" Female NPT | 4.0 | 0.35 | 57.2 | 28.6 | 14.3 | 52.5 | 19.8 | 82.8 | - | BS31-FF4N |

| 1/2" Female NPT | 1/2" Female NPT | 6.4 | 0.86 | 79.4 | 39.7 | 19.0 | 69.9 | 26.2 | 107.0 | - | BS31-FF8N |

| 1/4" Male NPT | 1/4" Male NPT | 4.0 | 0.35 | 57.2 | 28.6 | 12.7 | 63.5 | 19.8 | 82.8 | - | BS31-MM4N |

| 1/2"Male NPT | 1/2"Male NPT | 6.4 | 0.86 | 79.4 | 39.7 | 15.8 | 63.5 | 26.2 | 82.8 | - | BS31-MM8N |

| 14" Well-Lok | 14" Well-Lok | 4.0 | 0.35 | 71.6 | 35.8 | 12.7 | 52.5 | 19.8 | 82.8 | - | BS31-TT4 |

| 1/4" TSW | 1/4" TSW | 4.0 | 0.35 | 57.2 | 28.6 | 12.7 | 52.5 | 19.8 | 82.8 | 7.20 | BS31-TSW4 |

| 1/4" Male NPT | 1/4" Female NPT | 4.0 | 0.35 | 57.2 | 28.6 | 12.5 | 63.5 | 19.8 | 82.8 | - | BS31-MF4N |

| 1/2" Male NPT | 1/2" Female NPT | 6.4 | 0.86 | 79.4 | 39.7 | 19.0 | 69.9 | 26.2 | 107.0 | - | BS31-MF8N |

Dimensions shown with SEALEXCEL® Well-Lok™ Nut are finger tight

Dimensions are for reference only and are subject to change.