Advice for Selecting and Maintaining Three-Way Valves for air and hydraulic circuits

October 6, 2022

What is a Bleeder Valve? Working Principle & Function

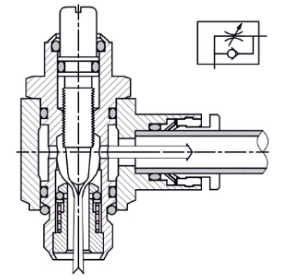

November 1, 2022A needle valve is a kind of valve that can be used to control how much gas or water flows through an appliance or system. The value is different because it comes with a tiny plunger that looks like a needle. The small handle on the plunger, called a handwheel, makes it easy and accurate to turn the valve.

When the valve is fully attached, the long end fits perfectly into what is called the seat, which is part of the device that is being controlled. However, if you turn the valve, space opens up between the needle and the seat. Only a tiny amount of substance can pass through the needle valve.

Like most valves, needle valves ensure that industrial machinery works safely and efficiently. Here is everything you need to know about your question to understand these standard industrial valves better.

Manufacture of Needle Valve

When needle valves are used, they have to hold back a lot of liquid and gas, which puts a lot of pressure on them. Chemicals in liquids and gases can damage many materials, so the valves must be made of solid material. Most people choose stainless steel because it is resistant to most chemical damage, corrosion, and rust and will last for years before it needs to be replaced.

It also does not need much care. Carbon steel and brass are two other materials that are often used. Another essential thing about needle valves is that they can withstand high temperatures. Most of the time, the liquids or gases being forced through the valves are very hot or cold. Both can cause damage, so special care must be taken during construction to protect the needle valves.

Needle valves are used in many different places and for many other purposes, and there are many kinds of needle valves to choose from, depending on your needs.

Needle Valves: The Pros

Flexibility

The most basic valves only have two settings. The flow is either open or closed. Needle valves are entirely different because you can choose from a wide range of options in the middle. You could set the flow to be very low but still moving, or almost as high as it can go but not quite. This gives a lot of flexibility. Most of the time, you should be able to change the valve to fit the situation.

Precision

Precision is always the most important thing to remember when it comes to a needle valve. This is the most crucial reason people usually choose this valve over another. Because the needle can be moved in such small amounts, the flow can be controlled in precise amounts. Because of this, the needle valve is a great choice when exact numbers and measurements are essential.

Increased efficiency

Users can be more efficient than ever because they have much control over the flow. Users can only use the exact amount of fuel or gas they need, so they don’t waste money or energy by letting much more flow than they need.

High safety levels

Because of how precise and flexible these valves are, they are also some of the safest on the market. Nothing goes through unless it’s supposed to, so there’s much less chance of leaks, breaks, or other damage that could cause dangerous situations.

One problem with needle valves is that you can’t tell how much pressure is being put on a system by looking at them. Since the valve works inside machinery and pipes, you don’t know how it works just by looking at it. There are times when different devices are added so that operators can track how much pressure is being put on a system. This is less of a problem with automated needle valve systems. Needle valves are made so that pressure can be added or taken away in minimal amounts. Needle valves are essential to many systems and machines because they help keep them in good shape and stop significant damage.