Precision Under Pressure: Why Mumbai’s Industries Rely on High-Pressure Stainless Steel Fittings

November 12, 2025

From Dairy to Dispensing: How Stainless Steel Connectors Keep Food Processing Safe in Mumbai

November 16, 2025Automation has revolutionized Mumbai’s manufacturing sector, increasing efficiency, precision, and output across industries. From automotive assembly lines to food and beverage production, automated systems rely on seamless connectivity and reliable components to maintain uninterrupted operations. Among these components, push-in tube fittings play a vital but often overlooked role, ensuring secure connections in pneumatic and fluid systems. These fittings are essential to maintaining the performance, safety, and longevity of automated machinery throughout Mumbai’s industrial landscape.

Enhancing Operational Efficiency

Push-in tube fittings simplify the process of connecting pneumatic and fluid lines, reducing installation time and labor costs. In Mumbai’s high-paced manufacturing environment, speed and accuracy are critical. These fittings allow operators to connect and disconnect tubes quickly without specialized tools, minimizing downtime during assembly or maintenance. The convenience of push-in fittings improves overall operational efficiency, allowing plants to meet high production demands while maintaining consistent quality.

Supporting Pneumatic and Hydraulic Systems

Many automated systems in Mumbai’s manufacturing plants rely on pneumatics and hydraulics to perform repetitive tasks with precision. Push-in tube fittings provide reliable connections for air and fluid lines, ensuring stable pressure and flow throughout the system. This maintains operational consistency and safeguards sensitive machinery from damage caused by pressure fluctuations. Whether in robotic arms, conveyor systems, or filling machines, these fittings are integral to seamless operation.

Reducing Maintenance Challenges

One of the key advantages of push-in tube fittings is their ability to simplify maintenance. Traditional fittings often require wrenches and extensive disassembly, increasing downtime and labor costs. Push-in fittings, however, allow for quick removal and replacement of tubes, making routine inspections, cleaning, and repairs faster and easier. This reduces the likelihood of extended downtime and keeps Mumbai’s manufacturing plants running efficiently.

Ensuring Safety and Reliability

In automated manufacturing, safety is paramount. Push-in tube fittings create secure connections that prevent issues that could disrupt operations or pose hazards to workers. Their robust design ensures consistent performance under high pressure and frequent use, providing peace of mind to plant managers and engineers. By maintaining system integrity, these fittings contribute to a safer and more reliable manufacturing environment across Mumbai.

Versatility Across Industries

Push-in tube fittings are used in a wide range of applications, from automotive and electronics manufacturing to food processing and pharmaceuticals. Their compatibility with various tubing materials and diameters, combined with ease of installation, makes them ideal for multiple industrial scenarios. As automation continues to expand in Mumbai, the demand for dependable, flexible, and efficient push-in fittings grows alongside it.

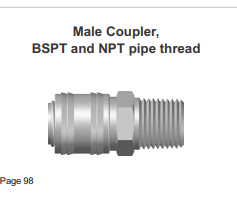

The Role of Stainless Steel Push-In Fittings

While push-in fittings are available in several materials, stainless steel push in fittings offer superior durability, corrosion resistance, and hygiene, making them ideal for critical applications in food, beverage, and pharmaceutical manufacturing. Their robust construction ensures long-term reliability in high-pressure and high-temperature environments, positioning them as the unsung heroes of Mumbai’s automated manufacturing plants.

Make Your Mumbai Industrial Operations Easier with SEALEXCEL

Upgrade your manufacturing systems in Mumbai with high-quality stainless steel push in fittings from SEALEXCEL. Ensure reliability, efficiency, and safety in your plant operations. Contact SEALEXCEL today to source durable and precision-engineered fittings.