An Outline of Sealexcel Quick Exhaust Valves

August 23, 2016Do you know what quick exhaust valves are? They are special fittings used in the different sectors of the industry for the purpose of increasing the cycle speed of a cylinder. The retraction and extension of the quick exhaust valve depends upon the actuation requirements of the system.

Features Of The Sophisticated Fittings

The quick exhaust valves are designed to be highly sensitive and exert differential pressure across the diaphragm to open the exhaust. The latest valves are now being design with a lightweight material, which can easily be supported by the piping of the system.

These corrosion resistant fittings have an oil resistant diaphragm, and the high quality fittings also ensure quite operations, unlike the usual chattering of the low quality valves. These valves ensure a rapid return and turn volume of the cylinder, and offer multiple porting options for efficient systems.

The swivel cylinder ports are also available for the critical alignment of the valves with the pneumatic system in the industry.

How They Are Used

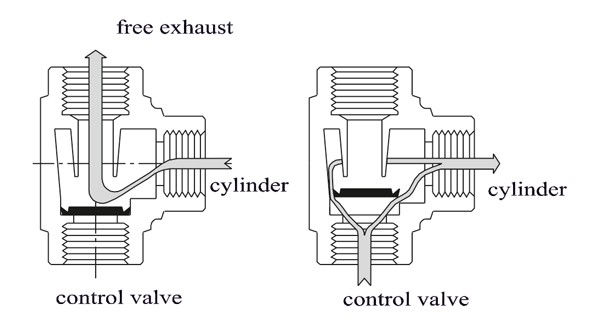

The valve is installed at the rod end or blind end of the cylinder, to offer a rapid extension and retraction of the equipment. When the exerted pressure is removed from the input port of the quick exhaust valve, the resultant back flow at the valve’s output port is sure to unseat the internal components of the valve. This entire process results in the relief of large amounts of liquid flow within the smallest amount of possible time.

These quick exhaust valves are available in both push to connect and threaded ports.

How The Valves Work

These valves work by increasing the speed of the cylinder rod in order to dump the exhaust air, at the port of the cylinder directly. The air is not directed at the back through the control valve. One quick exhaust is used in each port of the cylinder to ensure an increase in the speed of the rod in both directions.

The use of a quick exhaust valve helps to increase the cycling speed that ensures a much smaller and considerably smaller valve to be effectively used for the process. The air which enters the first port through the control valve, in effect bends the diaphragm to seal the third port, and enter through the second one. With the shift in the control valves, the exhaust air exits through the cylinder by the second port, which in turn pushes the diaphragm up at the same time sealing the first port. This way the air is allowed to exhaust through to the atmosphere through the third port.

The Application Of A Quick Exhaust Valve Cylinder

The application of a quick exhaust valve involves the installation of the fitting in the inlet of the spring return of a pneumatic cylinder or a double acting cylinder. They are available in a variety of shapes and sizes and are used in the industry to speed up the performance of a moving cylinder, evacuate air directly out into the atmosphere and increase the cylinder rod reaction time, or valve actuator.

High quality quick exhaust valves are the key to efficient functions in the industrial segments. for more information visit us at sealexcel.com