Want to Fix a Broken Pipe? Push Fittings to the Rescue!

March 20, 2017Things to Know About Push to Connect Air Line Fittings

March 20, 2020Push in pneumatic fittings are growing in popularity, and are easy to find in home improvement stores and hardware centers nowadays compared to traditional PVC, CPVC or sweat soldering copper pipes. These fittings are remarkably popular because of their ease of use and the fact that they require very little skill or important specialist knowledge to operate. The fact that no hazardous solvents are required for use is also a big reason for their increased adoption.

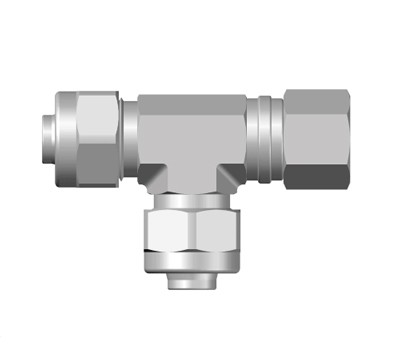

These fittings have a series of metallic spurs in the fittings that provide a tight grip to pipes when they are inserted into their respective fitting sockets. This firm grip on the pipes is crucial in maintaining stability and ensuring pipes don’t slide out of place. Push fit fittings are your best bet when making joints for a new installation using copper pipes, CPVC or PEX since Neoprene O-rings inside the fittings form tight waterproof seals against the installed pipes.

Despite being manufactured under various brand names, two of the most common being Sharkbite and Gatorbite they all have identical internal structures allowing them to function similarly as watertight seals when pushed onto a pipe. So what makes push-fit fittings more preferable to users today?

Why push-fit fittings are preferred

1. Quicker to Use

These fittings enable you to work with precision and speed. In a critical situation, it is possible to repair a pipe by simply pushing a push fit fitting. This saves time and facilitates less leakage.

2. Neat to Use

The use of push-fit fittings provides a clean and more aesthetically pleasing working area since you do not have to use a soldering gun, glue, and clamps. This makes the job neat and even easy to modify.

3. No Waiting Time

When you use CPVC and PVC the pipes must be very dry before glue or solvent can be applied. This means some waiting time has to be observed in case of rain or in the mornings before work can begin. This is not necessary with push fit fittings.

4. Readily Available

Nearly all types of pipes have corresponding push fit pneumatic fittings and they are also available in various materials. This makes them favorable for use.

5. Easily Removable

These fittings make it easy to modify especially if the connection was made as a temporary fix. This cannot be said for traditional methods such as gluing and soldering.

How to Use Push-Fit Fittings

1. Check the Pipes First

Check the pipes for any burrs at the end of pipes that can damage the O-rings in the fittings. Damaging the O-ring will compromise the watertight seal.

2. Purchase Fittings for Intended Use

Check the labels on the packaging before purchasing fittings to ensure they serve the intended purpose.

3. Follow Manufacturer’s Directions

When it comes to piping, make no assumptions. Ensure you follow the manufacturer’s directions and recommendations to ensure connections made are safe and watertight.

4. Get a Removal Tool

Even when acquiring push in pneumatic fittings for permanent repairs, it is advisable to acquire a tool that can disassemble the fittings whenever necessary.