Why Push-fit Fittings are Preferred and How to Fit Them?

March 19, 2020

Best Practices for Using Pneumatic Push-In Fittings

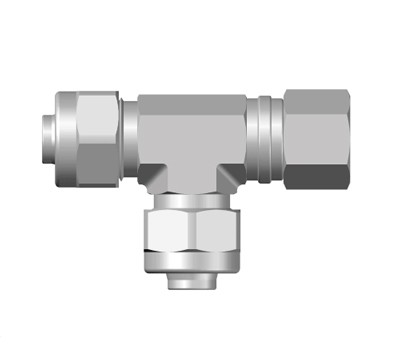

January 4, 2023Due to their resistance to aggressive industrial environment and corrosive substances, push to connect air line fittings are widely preferred in food processing, chemical, marine, packaging, and pharmaceutical industries. These fittings have compatibility with the tubes made with low-density polyethylene, copper, stainless steel, polyurethane, fluoropolymer, and semi-rigid nylon. They facilitate manual handling without any special tools. Using these fittings, you can make manual connections and disconnections. It facilitates full flow without any significant pressure drop. To ensure precision in their application, these fittings are made under strict quality controls. Apart from that, there are certain factors that must be analyzed for making the right selection. Here, they are:

The Material:

It is advisable to invest in the high-quality push to connect fittings made from sturdy materials. The high-grade 316 stainless steel is a commonly preferred option due to its durability and ability to withstand complex engineering environments. As per industry requirements, the high-quality fittings should be manufactured from raw materials that meet specifications of ASTM A-182 for SS-316 Forging and ASTM A-479 for SS-316 Bar Stock. All the components of fittings should be made from high-grade materials. Along with the material, you should also check the surface treatment of its components. Look for electropolished fittings having a corrosion resistant layer of chromium oxide coated on them.

The Sizing:

The push to connect fittings should be selected in a size that is suitable for your specific applications. In this regard, you should consider the fractional size and metric dimension of the fittings. Typically, their sizing is given in the form of OD or outer diameter. The fittings are available in the variety of sizes. You should choose them according to the recommended tolerance on the tube. The designs of fractional and metric-sized tubes are generally similar to each other. For identification purposes, they are made with a V-groove or some other sign.

The Operating Parameters:

When buying push to connect air line fittings, you should check their operating parameters on the basis of temperature and pressure ratings. In most of the applications, the fittings that can tolerate pressure up to 290 psi and temperature of 150 degrees Celsius are considered suitable.

The Customization:

Usually, these fittings are available in standard combination size and materials. But, you can get them customized according to specific requirements of your industrial applications. There are reputed manufacturers who provide customized combinations with NPT, BSPT, BSPP, and SAE pipe connections, tees, and cross unions. The fittings can also be manufactured in a suitable material.

When buying these fittings, you should lay your trust on a reputable manufacturer offering comprehensive warranty and complete technical support to the buyers. This helps in better selection of push to connect fittings when combined with the factors explained above.