Protect Your System with Sealexcel Stainless Steel Push-in-Fittings

August 5, 2016Want to Fix a Broken Pipe? Push Fittings to the Rescue!

March 20, 2017Manufacturers should pay equal attention to choosing the right kind of tubing and fittings as they pay to

First off, selecting the right tubing and fitting can be made easy by looking at the operation these components will be used for. As there are different types of tubing and fittings, you’ll know which to choose after going through this guide.

How to Select the Right Type of Tubing

It’s important to consider dimensions of fittings when it comes to selecting the right type of tubing. Remember that fittings and tubing will be attached TOGETHER. This is why dimensions of both should be precise.

People usually invest in fittings first, and then select the matching tubing or vice versa. SEALEXCEL recommends choosing tubing first.

There are two main types of tubing:

Soft Tubing

Often made out of norprene, silicone, rubber, PVC, or another special compound, soft tubing can be found very easily in the market. You can choose from 3 basic types—see-through, colored, and UV reactive tubing.

You cannot choose just any tubing from the local market, especially if you want to use it for your industrial water cooling unit.

Hard Tubing

The second type of tubing is known as ‘hard’ tubing. As the name suggests, hard tubing isn’t made of synthetic rubber or plastic, but harder materials. For liquid cooling, the most common hard tubes are made of acrylic (plexiglass) or PETG.

How to Select the Right Fittings Type

Fittings are widely in demand wherever tubing systems are in operation. The industrial and commercial world wouldn’t be able to function well without the right type of fittings to support the many systems and mechanisms that make industries operate well.

What Is A Fitting?

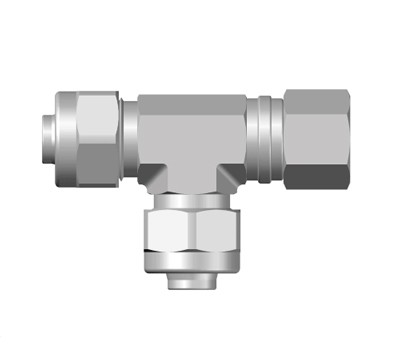

Fittings are manufactured in various sizes and shapes. One thing most fittings have in common? They are all easy to install and maintain.

SEALEXCEL manufactures fittings that can be used for different kinds of tubing. Some do require their own type of tubing. However, they all share some common features. Push-in fittings are the most commonly used fittings in many industries. SEALEXCEL as one of the leading push-in fittings supplier also manufactures pneumatic fittings, pneumatic couplings, and pneumatic connections. Stainless steel is the material used to manufacture all products.

Consider the following factors when selecting one:

- Connection Types

- Materials of Construction

- Check for Flow

- Type of Fitting

- Size

- Thickness

- Design

- Standards and Codes

If you require high quality push-in fittings, designed keeping international industrial standards in mind, then pay a visit to SEALEXCEL.