Three-Way Valves – Zero Leakage for All Industrial Applications

February 2, 2022

Guide On How To Choose The Right Plumbing Pipe for Your Need

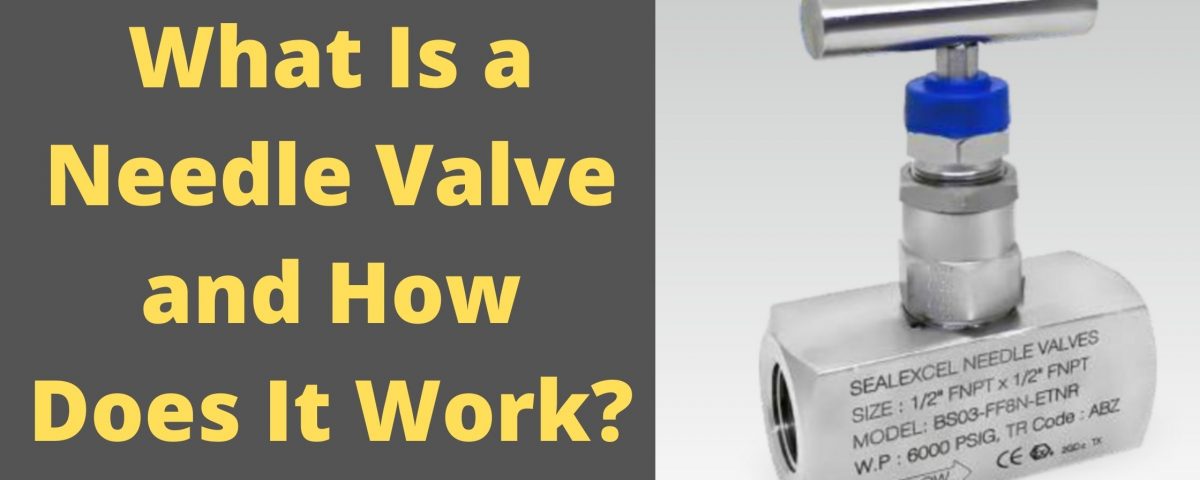

March 28, 2022A needle valve is a highly specialized valve commonly used in process industries for instrument installation. Needle valves allow the valve to open slowly and partially, which is advantageous since it does not “shock” the instrument to which it is attached. Because of its design, needle valves can also control flow and pressure. In this blog, let’s discuss in detail about the needle valve.

What is a needle valve?

The term “needle” refers to the valve’s design, in which the stem’s base is pointed like a needle and sealed to the valve body by pushing into a seat.

A needle valve is a type of valve that can control the flow of a substance through an appliance or system, commonly gas or water. Incorporating a small plunger with a needle-like shape is the value’s distinguishing feature. The plunger has a little handle, known as a handwheel, that allows the valve to be turned quickly and precisely. The elongated end of the valve, when fully attached, fits perfectly into the seat, a component of the appliance being regulated. However, when the valve is turned, the space between the needle and the seat opens up, allowing just a tiny amount of substance to travel through the needle valve.

Unlike conventional valves, which require only a quarter turn to fully open or close, stems are threaded, requiring up to 20 full spins to fully open or close the valve. When attempting to adjust flow rates or manage pressure, this provides high precision and enables a soft gradual opening or closing of the valve, eliminating rapid changes in the associated devices.

How do needle valves work?

To open and close an orifice, needle valves have a tapered end that raises and lowers with the turn of a handle. The plunger, also known as a stem, is connected to the handle, and when you turn the handle, the plunger moves up or down based on the threads. As the plunger descends, the locking nut prevents it from totally unscrewing, and the tapered, pointed end makes contact with the valve seat to seal the opening fully; the valve seat is commonly tapered as well. The port connection on the input and output can be attached to a pipe or hose in various sizes, while the bonnet is connected to the valve housing, which can be made of stainless steel.

Needle Valve Usage

Needle valves are found in various systems and applications, including carburettors used to manage pressure inside a device, which can also be found in some water heaters.

This can also ensure that the appliance is operating at optimal efficiency while consuming the least amount of water possible and can be used to manage product distribution and relieve pressure on the systems that distribute the relevant substances on a bigger scale and to a large number of users.

Needle valves are also employed in vacuum systems to release a steady but constant gas supply without removing pressure. The valve allows the gas flow to be delayed significantly before being shut off, while internal machinery and components will be less stressed and strained due to this.

Seal Excel, the best needle valves manufacturers in India, has its Needle Valves with various stems to give you more options. The standard self-centring, non-rotating stem tip is generally utilized in high-cycle applications to extend valve life.

In addition, each valve is factory checked for leakage at the seat and packed with nitrogen at 1000 PSIG (69 bar) pressure. We also do optional hydrostatic testing using de-ionized water at 1.5 times the working pressure.