How to Choose the Right Quick Connect Fittings Supplier in Mumbai

July 29, 2025

The Role of NSF Approved Fittings in Food & Beverage Dispensing Equipment

August 18, 2025At the heart of India’s manufacturing landscape, Mumbai’s OEMs are continually seeking ways to streamline production, minimize downtime, and simplify system integration. Whether in the automotive sector, heavy machinery, or industrial automation, one small component is making a big impact—push-in tube fittings.

These compact connectors offer rapid assembly, minimal maintenance, and a leak-free seal, ensuring consistent performance. As a result, push-in tube fittings in Mumbai are now a critical choice for OEMs aiming to enhance both speed and reliability on the assembly floor.

Tool-Free Installation Speeds Up Production

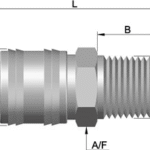

One of the biggest advantages of push-in fittings is their rapid assembly. Unlike threaded fittings that require sealants and torquing, push-in tube fittings are designed for fast, tool-free connection. This is especially important for OEMs working under tight deadlines, where every second counts. In high-throughput sectors like automotive manufacturing, the ease of installation directly contributes to lower labour costs and faster cycle times. OEMs are now prioritizing fittings that eliminate complexity, and push-in technology fits perfectly into that requirement.

Leak-Free Performance Reduces Downtime

Even a minor air leak in a pneumatic system can cause pressure drops, energy loss, and reduced actuator performance. That’s why quality push-in tube fittings in Mumbai are engineered with precision tolerances and secure gripping mechanisms to ensure an airtight seal.

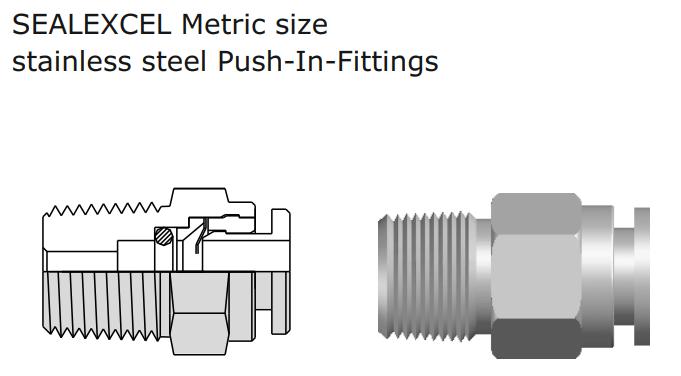

For manufacturers in the automotive and machinery assembly industries, this means fewer stoppages and more reliable system performance. Sealexcel, a leading manufacturer of pneumatic fittings in Mumbai, offers stainless steel and polymer push-in designs that are rigorously tested for long-term leak resistance in demanding environments.

Compact Design Maximizes Equipment Flexibility

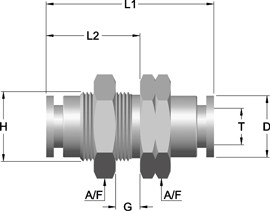

Space-saving is another key reason OEMs are shifting toward push-in fittings. Traditional configurations can occupy more space and limit design options in tight installations. With their low-profile and modular nature, stainless steel push-in fittings in Mumbai allow engineers to build compact, efficient systems without compromising airflow or pressure integrity. These fittings also support easy reconfiguration, allowing for quick system adaptations on the factory floor.

Designed for leak-free and tool-free installation, Sealexcel’s push-in tee fittings support faster assembly and modular design across modern OEM production lines in Mumbai.

Versatility Across Pneumatic and Hydraulic Systems

While traditionally used in pneumatic setups, modern push-in fittings have evolved to handle light hydraulic applications as well. This has broadened their use across various sectors, including material handling, packaging automation, and industrial robotics. Many OEMs now rely on pneumatic quick-connect couplings in Mumbai alongside push-in tube fittings to create flexible, scalable platforms that can adapt to changing process demands. The versatility of push-in fittings makes them a valuable addition to any system design strategy.

Consistent Quality From Trusted Local Suppliers

Another reason for the surge in adoption is access to local manufacturing excellence. As a seasoned push-in fittings supplier in Mumbai, Sealexcel provides OEMs with the assurance of precision-machined fittings, timely delivery, and technical support. Working with a domestic manufacturer not only reduces lead times but also ensures product compatibility with Indian industrial standards and working conditions.

If you’re ready to optimize your pneumatic or light hydraulic systems, now is the time to upgrade to high-performance push-in fittings. At Sealexcel, we design and manufacture fittings that meet the needs of modern OEMs—reliable, easy to use, and built for long-term performance.

Reach out to us here to explore our full range of push-in tube fittings and discover how we can help you boost efficiency across your production line.