Decoding the Maze: A Guide to Every Hydraulic Connector Type

January 18, 2024

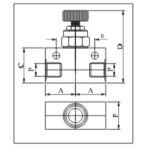

Hydraulic Flow Control Valve: Master Fluid Power with Precision

May 15, 2024Introduction

Hydraulic fittings play a pivotal role in the functionality and efficiency of fluid power systems. Hydraulic fittings are ubiquitous in various applications, from heavy machinery in industrial settings to the brakes in our automobiles. But what exactly are Hydraulic Fittings, and why are they so crucial?

I. What are hydraulic fittings?

Hydraulic fitting are components used to connect hydraulic hoses, tubes, and pipes in fluid power systems. They ensure leak-free connections while allowing fluid to flow between different elements, such as cylinders, pumps, and valves.

Why are hydraulic fittings crucial in fluid power systems?

Hydraulic fittings provide the vital links that enable hydraulic systems to operate smoothly and efficiently. They facilitate the transfer of hydraulic fluid under high pressure, allowing machines and equipment to perform tasks with precision and power. Hydraulic systems would be prone to leaks, pressure loss, and potential failures without adequately functioning fittings.

II. Types of Hydraulic Fittings

Understanding the different types of hydraulic fitting is essential for selecting the right components for specific applications.

What are the different types of hydraulic fittings available?

- Compression fittings: These fittings utilize compression to secure pipes or tubes together.

- Flare fittings: Flare fittings feature a flared end that seals against a mating surface, ensuring a tight connection.

- Pipe fittings: Pipe fittings, such as elbows, tees, and couplings, join pipes of varying sizes and shapes in hydraulic systems.

III. Components of Hydraulic Fittings

Hydraulic fittings consist of several components that contribute to their functionality and reliability.

What are the primary components of hydraulic fittings?

- Materials: Hydraulic fitting are commonly made from materials like steel, brass, or stainless steel, chosen for their durability and resistance to corrosion.

- O-rings and seals: These components ensure leak-free connections by creating a tight seal between fittings and mating surfaces.

- Threads: Threads allow fittings to be securely screwed onto hoses, tubes, or pipes, maintaining a tight and stable connection.

IV. Hydraulic Fittings in Action

Hydraulic fittings facilitate fluid transfer and control within hydraulic systems, enabling machines to perform various tasks efficiently.

How do hydraulic fittings facilitate fluid transfer and control?

Hydraulic fittings allow hydraulic fluid to flow seamlessly between different hydraulic system components, such as cylinders, motors, and control valves. They regulate the direction, pressure, and fluid volume, enabling precise control over machinery and equipment.

V. Selection Criteria for Hydraulic Fittings

Choosing the right hydraulic fitting is crucial for ensuring optimal performance and reliability of fluid power systems.

What factors should one consider when selecting hydraulic fittings?

- Pressure ratings: Fittings must be rated to withstand the maximum pressure of the hydraulic system to prevent failures and leaks.

- Temperature limitations: Fittings should withstand the extreme temperatures experienced in the operating environment without compromising performance.

- Compatibility: Fittings must be compatible with the type of hydraulic fluid used in the system to prevent chemical reactions or degradation.

VI. Installation and Maintenance of Hydraulic Fittings

Proper installation and maintenance are essential for ensuring the longevity and performance of hydraulic fitting.

How should hydraulic fitting be installed correctly?

Hydraulic fittings should be installed following manufacturer guidelines, ensuring proper torque, alignment, and thread engagement. Care must be taken to avoid over-tightening, damaging fittings, or compromising seals.

VII. Common Challenges and Troubleshooting

Despite their importance, hydraulic fittings are susceptible to specific challenges that can affect system performance.

What are some common issues encountered with hydraulic fittings?

- Leaks: This can occur due to damaged seals, loose fittings, or improper installation.

- Fitting failures: Fittings may fail under high pressure or due to corrosion, leading to system malfunctions.

- Pressure loss: Improperly sized or fitted fittings can result in pressure loss within the system, affecting performance.

VIII. Safety Considerations with Hydraulic Fittings

Safety should be a top priority when working with hydraulic systems and fittings to prevent accidents and injuries.

Why is safety paramount when dealing with hydraulic systems?

Hydraulic systems operate under high pressure and contain potentially hazardous fluids. Proper safety protocols, including wearing protective gear and following established procedures, are essential to prevent accidents and injuries.

IX. Future Trends and Innovations

Advancements in technology and materials are driving innovation in hydraulic fitting, leading to more efficient and reliable systems.

What advancements are shaping the future of hydraulic fittings?

- Emerging materials: Advances in materials science are leading to the development of lightweight yet durable fittings capable of withstanding harsh operating conditions.

- Bright fittings: Integration of sensors and monitoring systems allows for real-time monitoring of hydraulic fitting, enabling predictive maintenance and troubleshooting.

X. Conclusion

Hydraulic Fittings are integral components of fluid power systems, enabling the efficient transfer and control of hydraulic fluid. Understanding the different types of fittings, their components, and selection criteria is essential for ensuring optimal system performance and reliability. Hydraulic systems can operate safely and effectively in various applications by following proper installation and maintenance practices and prioritizing safety. As technology continues to evolve, future innovations in hydraulic fitting promise to enhance system efficiency and reliability further, driving advancements across industries.