How The Ball Valve Can Make A Big Difference In The Gas Refinery Process

May 26, 2016Manifold Valves And Under-floor Heating

June 21, 2016Precision type fittings are important for making sure all pipes and components fit together seamlessly and lead to smooth operations.

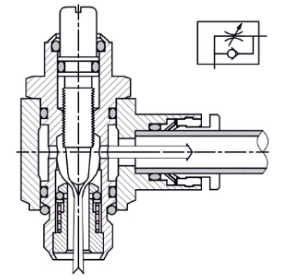

Used mainly for process control and instrumentation, precision type fittings come in a range of shapes, configurations, and sizes to meet individual client needs.

The following is a guide that contains all you need to know about precision type fittings.

Types of Precision Type Fittings

All precision type fittings are manufactured according to standard industry specifications and designed to comply with quality control certifications, such as ISO 9001:2000.

Although many precision type fittings are made from stainless steel, there are also pipes that are manufactured from materials, such as titanium, hastelloy C, monel, brass, and inconel. There are also a range of precision type fittings, such as street elbow, reducing street elbow, branch tee, cross, hex coupling, pipe cap, adapter, hex brushing, and union ball joint.

Features and Benefits of Precision Type Fittings

Precision type fittings are manufactured in size range between 1/8” and 1” with 316 brass, stainless steel, and other materials, in addition to being fitted with NPT threads.

The fittings also have heat traceability and high pressure ratings, making it great for withstanding heavy loads and gas pressures. Its exposed threads are covered with plastic caps to prevent leakages, cleanliness, and efficient seal against components.

Precision type fittings, as a result of these features, provide various advantages. Its efficient heat traceability and considerable pressure rating makes it effective for use in temperatures as high as 100 degrees Fahrenheit depending on what material the fittings are made of.

If it is made from stainless steel, the more likely it will be resistant to high temperatures.

More importantly, the way in which precision type fittings are designed ensure leakages are not a possibility, making it ideally suited for use in oil and gas, petrochemical and power plant, packaging, and printing industries. All components and parts of precision type fittings are easy to understand and connect, which also leads to quick installation and replacement.

Safety Precautions That Must Be Taken Into Account

Despite its benefits and features, it is advised to consider the many safety precautions that must be considered prior to use. Firstly, no attempt must be made to loosen the precision type fitting if the system is pressurized.

Doing so can vent out highly pressured gas and can lead to damage to components or worse, injuries. Additionally, extra caution must be used when dealing with toxic or hazardous substances to ensure smooth operations.

We, at Sealexcel, have more than two decades of experience in manufacturing a range of fittings and valves, from stainless steel push-in fittings to purge valves, in accordance with the highest quality standards and certifications. To learn how precision type fittings apply to your industry, check out our industrial products.