How to ensure the most satisfying fitting for your machinery

December 8, 2016What You Need to Know About Check Valves and Their Sizes

January 10, 2018Block and bleed valves are hydraulic manifold systems that provide a single component interface by combining a number of valves, particularly ball and needle valves. They are commonly used in the oil and gas industry and are beneficial in ensuring the supply of liquid upstream does not affect the system components downstream.

Knowing the types and advantages of block and bleed valves can be important when undertaking an industrial or commercial project.

In this post, we explore how block and bleed valves work, its different types, and advantages they offer.

How do Block and bleed Valves Work?

The block and bleed valve can be operated to restrict liquid from flowing into a particular component and later letting it flow out of the manifold.

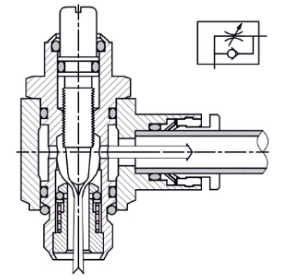

Double block and bleed valves, for instance, are single valves that have two seating surfaces. If the valve is closed, it offers an effective seal from both surfaces that allow the liquid to vent out. This type of isolation occurs when only one of the sides faces pressure.

Types of Block and bleed Valves

Different types of block and bleed valves offer different features. Block and bleed valves are also known as isolation valves or isolation manifolds. A manifold that features a number of valves is useful for using it in gas trains, as well as in various industrial contexts.

Other types of block and bleed valves include the double block and bleed valves, three piece non standard length double block and bleed valves, block and bleed needle valves, single unit double block and bleed valves, and cartridge type length double block and bleed valves.

The standard double block and bleed valves, for instance, are used for chemical injections under high pressure environments or for handling toxic fluid processes. Needle valves, on the other hand, are used in pneumatic and hydraulic systems.

Benefits of Block and Bleed Valves

Block and bleed valves are beneficial for preventing leakages or mixing of fluids with critical components. This makes it ideal for use in petrochemical environments where there is a need to handle and manage toxic waste and other dangerous chemicals.

The interlocking provided in the valve allows easy venting of the liquids and provides considerable safety in high-risk environments.

Furthermore, block and bleed valves are important for bringing operation and production costs to a minimum. The efficiency of the valves prevents the need for multivalve systems and ensures high project operational efficiency in a range of industries from LNG and petrochemical to natural gas processing.

If you are interested in using bleed and purge valves or wish to know more information about our range of flow control regulators, please contact us today.