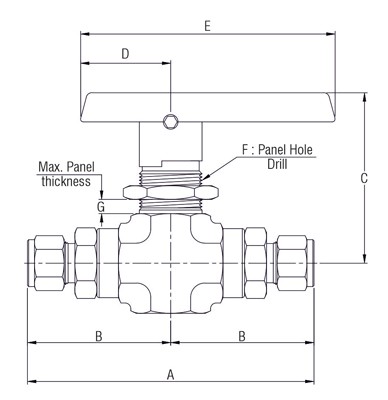

STANDARD CONFIGURATION DIMENSIONS

| End Connections |

Orifice |

Cv |

Dimensions (mm) |

Ordering

Number |

|

Inlet |

Outlet |

A |

B |

C |

D |

E |

F |

G |

| 1/8" Well-Lok |

1/8" Well-Lok |

2.4 |

0.21 |

69.0 |

34.5 |

25.0 |

19.1 |

47.8 |

14.7 |

3.3 |

BV105L-TT2 |

| 1/8" Female NPT |

1/8" Female NPT |

4.2 |

0.93 |

54.4 |

27.2 |

25.0 |

19.1 |

47.8 |

14.7 |

3.3 |

BV105L-FF2N |

| 1/8" Male NPT |

1/8" Male NPT |

4.2 |

0.93 |

60.0 |

30.0 |

25.0 |

19.1 |

47.8 |

14.7 |

3.3 |

BV105L-MM2N |

| 1/4" Male NPT |

1/4" Male NPT |

4.2 |

0.93 |

68.6 |

34.3 |

25.0 |

19.1 |

47.8 |

14.7 |

3.3 |

BV105L-MM4 |

| 3mm Well-Lok |

3mm Well-Lok |

2.2 |

0.18 |

68.8 |

34.8 |

25.0 |

19.1 |

47.8 |

14.7 |

3.3 |

BV105L-TT3M |

| 1/4" Well-Lok |

1/4" Well-Lok |

4.7 |

1.04 |

88.4 |

44.2 |

41.5 |

25.4 |

63.5 |

19.6 |

6.4 |

BV105L-TT4 |

| 1/4" Female NPT |

1/4" Female NPT |

6.4 |

2.34 |

76.8 |

38.4 |

41.5 |

25.4 |

63.5 |

19.6 |

6.4 |

BV105L-FF4 |

| 1/4" Male NPT |

1/4" Male NPT |

6.4 |

2.34 |

82.2 |

41.1 |

41.5 |

25.4 |

63.5 |

19.6 |

6.4 |

BV105L-MM4 |

| 3/8" Well-Lok |

3/8" Well-Lok |

6.4 |

2.34 |

91.4 |

45.7 |

41.5 |

25.4 |

63.5 |

19.6 |

6.4 |

BV105L-TT6 |

| 6mm Well-Lok |

6mm Well-Lok |

4.7 |

1.04 |

89.0 |

44.5 |

41.5 |

25.4 |

63.5 |

19.6 |

6.4 |

BV105L-TT6M |

| 8mm Well-Lok |

8mm Well-Lok |

6.4 |

2.34 |

90.4 |

45.2 |

41.5 |

25.4 |

63.5 |

19.6 |

6.4 |

BV105L-TT8M |

| 10mm Well-Lok |

10mm Well-Lok |

6.4 |

2.34 |

92.0 |

46.0 |

41.5 |

25.4 |

63.5 |

19.6 |

6.4 |

BV105L-TT10M |

| 3/8" Female NPT |

3/8" Female NPT |

10.3 |

6.42 |

99.0 |

49.5 |

66.5 |

38.1 |

101.6 |

22.9 |

9.7 |

BV105L-FF6 |

| 1/2" Female NPT |

1/2" Female NPT |

10.3 |

6.42 |

109.2 |

54.6 |

66.5 |

38.1 |

101.6 |

22.9 |

9.7 |

BV105L-FF8 |

| 1/2" Well-Lok |

1/2" Well-Lok |

10.3 |

6.42 |

118.8 |

59.4 |

66.5 |

38.1 |

101.6 |

22.9 |

9.7 |

BV105L-TT8 |

| 1/2" Male NPT |

1/2" Male NPT |

10.3 |

6.42 |

112.8 |

56.4 |

66.5 |

38.1 |

101.6 |

22.9 |

9.7 |

BV105L-MM8 |

| 3/4" Well-Lok |

3/4" Well-Lok |

10.3 |

6.42 |

118.4 |

59.2 |

66.5 |

38.1 |

101.6 |

22.9 |

9.7 |

BV105L-TT12 |

| 12mm Well-Lok |

12mm Well-Lok |

9.5 |

5.57 |

118.4 |

59.2 |

66.5 |

38.1 |

101.6 |

22.9 |

9.7 |

BV105L-TT12M |

| 16mm Well-Lok |

16mm Well-Lok |

10.3 |

6.42 |

118.4 |

59.2 |

66.5 |

38.1 |

101.6 |

22.9 |

9.7 |

BV105L-TT16M |

Dimensions shown with SEALEXCEL® Well-Lok™ Nut are finger tight

Dimensions are for reference only and are subject to change.