Manifold Valves And Under-floor Heating

June 21, 2016Corrosion Resistant Alloys: Saviors for Marine Industry?

August 4, 2016A number of different processes are involved in the manufacturing of a single loaf of bread. Packaging, testing, and transportation of the final product are important operations.

However, what is even more important is the smooth working of the different machines and equipment in the factory. Industrial valves are responsible for this.

What Are Industrial Valves?

A valve is defined as: an industrial implement that is responsible for regulating and directing flow of liquids, gases, fluidized solids, etc. This operation is carried out by the opening, closing, or partial obstruction of various passageways.

Even though valves are technically fittings, they perform the work of controlling fluids from one end to the other. There are many types of industrial valves available in the market, two of which are detailed below:

Ball Valve

This type of valve features a spherical disc through which flow of fluids or gases is controlled. The sphere is designed with a hole or port, cut through the middle by which flow operation (i.e. when the hole is in line with both ends of the device) can take place. The ball valve comes from the family of quarter turn valves.

Ball Valves Are Popular Because…

- They are durable.

- They work just fine even after years of disuse.

- They are incredibly versatile.

- Depending on design and material, they can handle temperatures up to 204°C.

- They are easy to operate, maintain and repair.

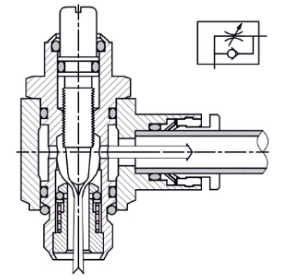

Check Valve

Also known as one-way or non-return valve, this type of valve normally allows flow of liquid or gas in one direction only. These valves have two ports, i.e. two openings in the device – one for fluid entry and the other for fluid exit. Check valves are versatile which is why many industries use these implements in a number of applications. Check valves can also be found in the household – in kitchen and bathroom plumbing for example. The external body of most check valves is made of either plastic or metal.

An Important Consideration for Check Valves

It’s the minimum upstream pressure that the check valve will operate at without cracking. Typically, all our check valves are specifically designed for a certain cracking pressure and can therefore handle any application.

Valves are important to the smooth and efficient operation of every factory setting. Make sure the industrial implements are designed with standards and specifications that are unique to your application. Call SEALEXCEL today to learn more about our standards for designing industrial valves and tube fittings.