Guide On How To Choose The Right Plumbing Pipe for Your Need

March 28, 2022

A Handy Guide to Stainless Tube Compression Fittings

March 30, 2022A pipe coupling is an important part of connecting pipe sections and keeping the pipes safe at the same time. It is very important for people who work with pipes and plumbing to have this pipe fitting. It is common for pipes to need to be cut or joined together to make changes in direction and cross over things like fences and pipes.

This is a very short piece of pipe or tube. It has socket or female pipe threads at one or both ends that can be used with pipes. Two pipes or tubes of different sizes can be joined together to run a long pipe. Pipe couplings are used to do this.

The different types of pipe couplings

Full Coupling

Full coupling is used to connect pipes that are small. It was used to connect pipes to swage or nipples or pipes to pipes. A socket weld is a way to join two pieces of metal together. Full couplings are used to connect small-bore, plain end pipes where the pipe spec requires a socket weld and full couplings are used. It is used to connect small pipes with threaded ends to each other. This is called an adapter if the two ends of the coupling are different like one BSP threaded and the other NPT threaded.

Half Coupling

Half pipe couplings are used when you want to branch off from a vessel or pipe with a lot of space. There are two ways it can be: threaded or socket type. On one side, it has a socket or thread end that can be used to connect things.

A socket weld is a way to join two pieces of metal together. A half coupling can be weld on directly to a large bore pipe so that a branch can be made. To take a small bore pipe off of a large bore pipe. There is only one thread end on a threaded half coupling. The other end of the coupling should be a butt-welding end with either a plain end or a beveled end.

Reducing Coupling

It is used to connect pipes with different diameters. On each side, the threads are the same size. A reducing coupling has two different sizes on each side. If you want to connect small process feeder lines to large supply circuits, or if you want to use smaller fittings, you might use reducing couplings instead.

Simple, stepped-down couplers are used to reduce the length of two pipes. They screw onto the two pipe couplings lengths like a standard pipe joint screws on. Welded reducing couplers look like threaded couplers but without the threads.

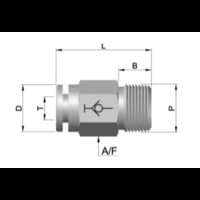

Compression Coupling

This coupling connects two aligned pipes. A slotted tapered sleeve is placed over the junction, and two flanges are drawn over the sleeve to center the pipes and provide enough pressure automatically.

This is called slip coupling when a couple slips or needs to be fixed. Two pipes can slide out of the other pipe to different lengths in a slip coupling. This is also called a repair coupling. You can use a slip coupling when you need to fix a pipe with a small leak because of corrosion or freezes bursting or because you had to cut it short. It has no internal stop to slip it into place in tight places. The installer should ensure that the slip coupling is in the right place before putting it in place because the alignment stop is not there.

Pipe couplings are used to connect two pipes that have the same diameter to each other. Couplings also come in handy if the pipe is broken or leaks. Usually, two types of couplings can be used. Compression coupling and slip coupling are two ways to connect things. Compression coupling is a type of regular coupling that connects two pipes.

It stops leaks by having gaskets or rubber seals on both sides, or glue is used instead. Slip couplings are easier to put together and have two pipe couplings that slide together. The inner pipe can slide up to a certain length. Therefore, we can fix a long pipe where slip joints have been damaged.