3 Innovation Trends That Will Change The Maritime and Shipbuilding Industry

May 5, 2016How The Ball Valve Can Make A Big Difference In The Gas Refinery Process

May 26, 2016Industrial valves are important to your manufacturing processes. If not maintained, the entire process, including distribution

The instrumentation valves will, over time, lose their functionality and quality, which becomes even more potent if maintenance isn’t given its due importance and attention.

The industrial valves and tube fittings you install in your machines will work for a long time if maintained properly. On the other hand, even the most expensive and high quality valve can lose their function if left to erode.

Following is a helpful maintenance guide by SEALEXCEL, one of the leading tube fittings and valves manufacturers in India.

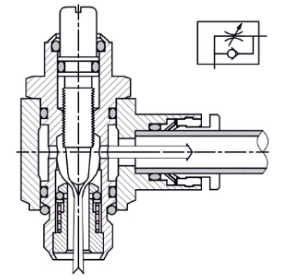

Installation, Operation, and Disassembly Instructions

With every delivery, SEALEXCEL also provides easy to follow instructions on how to properly install, operate and disassemble valves. Clients are also guided through some inspection tips, either on the phone or via online query.

Valve Lubrication

Better and consistent performance is the benefit of valve lubrication. Technicians at SEALEXCEL suggest regular lubrication of installed valves even if the item performs a simple task (like an opening and closing action). Another important point: lubricating two surfaces that slide continuously over one another is a must-do.

Lubrication and Assembly by SEALEXCEL

Every industrial valve and tube fitting manufactured by the Mumbai based company goes through rigorous testing at our state-of-the-art in-house testing facilities. To prevent galling, reduce friction and make sure the valve functions and seals properly,

Valve Flush Plugs

This product helps protect the rest of the piping system from contamination (if one section needs to be flushed, cleaned or altered). You can find three types of valve flush plugs in the market;

Under-Seat: These provide a trouble-free connection to the flushing pump.

Flow-Thru: is inserted in valves (in middle of the section) and then cleaned or flushed.

Over-Seat: Provides the same easy accessibility to the flushing pump as the under-seat.

Cleaning and Drying By SEALEXCEL

Using their two decade worth of experience and expertise in industrial valve manufacture, SEALEXCEL has developed highly effective multi-processes through which each and every part and component is cleaned. The processes involve cleaning, rinsing and drying which removes dirt, oils and loose particles that may have accumulated during manufacture.

The function and overall performance of your industrial valve will decline with over-time usage. This doesn’t mean users should buy and install cheap quality valves and tube fittings, thinking replacing them will be more cost effective than buying high quality ISO 9001:2008 approved and complaint instrumentation valves and tube fittings. Check out the extensive product catalogue offered by SEALEXCEL today.