Manifold Valves : Series - MFV5 (Five Way)

FEATURES

- Available in SS316, NACE certified on request

- Heat Code Traceable to certified material test report

- Low operating torques

- PTFE packing standard, Graphite packing for high temperature on request

- Available with 2 way, 3 way and 5 way valve.

- Available with Pipe to Pipe, Pipe to Flange, Flange to Flange, Remote, Remote mounting Base vent, Base, Direct and Integral mounting.

- Convenient method of blocking, bleeding and calibrating pressure instruments.

- Designed for connection system impulse line & transfer

- Combine the function of a tee, calibration valve, isolation valve, all tubing and fittings in a sigle valve configuration.

- Standard port sizes up to 1/2” NPT/BSP/BSPT

- Every valve is factory tested

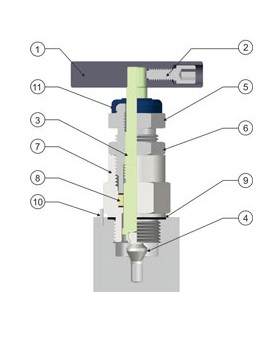

STANDARD BONNET DESIGN FOR SAFE AND RELIABLE PERFORMANCE

| Description | Features and Benefits |

| 1. Bar Handle | To operate and control the valve flow. |

| 2. Set Screw | Lock the handle with stem. |

| 3. Stem | i) Rolled and silver plated stem threads for excellent performance and extended service life. ii) Burnished stem at packing area to ensure low torque operation of the valve & reduction in packing wear |

| 4. Stem Tip | 17‐4 PH Stainless Steel hardened non rotational self centering stem tip for superior and repeatable positive bubble tight shut off. |

| 5. Packing Adjuster | Makes external adjustment to set the perfect sealing of gland packing. |

| 6. Lock Nut | For safety to prevent accidental valve disassembly. |

| 7. Bonnet | Directly screwed to the main body. |

| 8. Packing | Packing below the threads protects the flow stream from lubricant contamination on the threads or wash out and also protect the stem threads from potential damaging effects of the media. |

| 9. Washer | For sealing between body and bonnet assembly. |

| 10. Locking Pin | To prevent accidental loosening / disassembly of valve. |

| 11. Dust Cap | Protects the stem from foreign particles. |

OPERATING PARAMETERS

- Pressure Rating : upto 6000 psig (408 bar) at CWP

- Temperature Rating : -54ºC to 232ºC with PTFE packing, upto 428ºC with optional graphite packing

APPLICATION

- Pressure and Differential pressure Instrumentation

TESTING

- Standard Test : Each valve is factory tested with nitrogen at 1000 psig (69 bar) for leakage at the seat and packing.

- Optional Hydrostatic test : This test is performed with de-ionised water at 1.5 time the working pressure.