Purge Valves : Series - PGV

FEATURES

- Available in material SS316

- Heat Code Traceable to certified material test report

- Compact and convenient installation

- Vent hole in the cap bleeds, drains or purges system pressure

- Cap is crimped to valve body to prevent accidental disassembly

- Require only quarter turn with a wrench from finger tight position to ensure a leak tight seal

- Variety of end configurations includes SEALEXCEL® Well-Lok™ Tube Fittings Male/Female NPT and SAE pipe connections

- Every valve is factory tested

OPERATING PARAMETERS

- Pressure Rating : upto 4000 psig (276 bar) at CWP

- Temperature Rating : -54°C to 232°C

APPLICATION

- General Plant Service

- Instrumentation

- Hydraulic and Pneumatic

- Venting

MATERIAL OF CONSTRUCTIONS

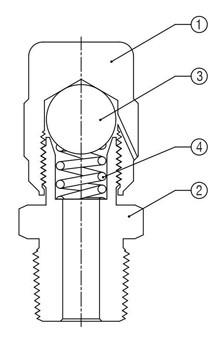

| No. | Component | Material |

| 1 | Cap | SS316 |

| 2 | Body | SS316 |

| 3 | Ball | SS316 |

| 4 | Spring | SS316 |

TESTING

- Standard Test : Each valve is factory tested with nitrogen at 1000 psig (69 bar) for leakage at the seat.

- Optional Hydrostatic test : This test is performed with de-ionised water at 1.5 time the working pressure

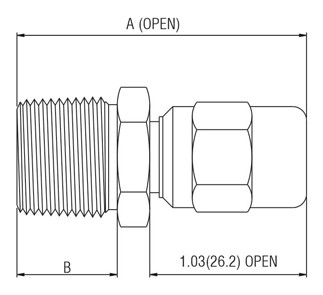

STANDARD CONFIGURATION DIMENSIONS

| End Connections | Dimensions inch (mm) | Ordering Number |

| Inlet | A B | |

| 1/8" Female NPT | 1.56 (39.6) 0.53 (13.5) | PGV-F2N |

| 1/4" Female NPT | 1.75 (44.4) 0.72 (18.3) | PGV-F4N |

| 3/8" Female NPT | 1.81 (46.0) 0.78 (19.8) | PGV-F6N |

| 1/2" Female NPT | 1.98 (50.3) 0.97 (24.6) | PGV-F8N |

| 1/8' Male NPT | 16.2 (41.1) 0.38 ( 9.7) | PGV-M2N |

| 1/4" Male NPT | 1.81 (46.0) 0.56 (14.2) | PGV-M4N |

| 3/8" Male NPT | 1.84 (46.7) 0.56 (14.2) | PGV-M6N |

| 1/2" Male NPT | 2.09 (53.1) 0.75 (19.1) | PGV-M8N |

| 1/8" Well-Lok | 1.84 (46.7) 0.59 (15.0) | PGV-T2 |

| 1/4" Well-Lok | 1.94 (49.3) 0.69 (17.5) | PGV-T4 |

| 3/8" Well-Lok | 2.03 (51.6) 0.75 (19.1) | PGV-T6 |

| 1/2" Well-Lok | 2.19 (55.6) 0.88 (22.4) | PGV-T8 |

| 6mm Well-Lok | 1.94 (49.3) 0.69 (17.5) | PGV-T6M |

| 8mm Well-Lok | 2.00 (50.8) 0.72 (18.3) | PGV-T8M |

We offer the stainless steel purge valve 316 series at the best cost, designed to ensure flawless industry application processes and working. If you are looking for industry standard and quality approved Purge Valves, to comply with the complex needs of your industry, then provide us with the unit specifications and we will offer you a unit design best suited to your needs.

We are experienced Purge valve Manufacturers and take pride in only offering quality designed products to our industrial customers.

Key Product Characteristics of the Purge Valves

Some of the most important key features of our designed and manufactured purge valves are,

Cost effective

Units designed with an operating parameter pressure rating of up to 689 bar and 10,000 psig. It is measured at CWP.

The Purge Valve is designed with an orifice size which measures 3.20mm or 0.125 inches

The flow co-efficient value of our designed Purge Valves is taken to 0.25Cv.

Each unit is designed with a sophisticated vent hole structure, built to help the purge cap bleed out or drain the system pressure for safety

The vent tube which is part of the valve design, is used to direct away any excess gas or liquid from the operational system line

We offer a variety of Purge Valve end configurations to choose from, which include the BSPT pipe connection, our

Well Lok tube fittings, as well as the female/male NPT to suit our customer needs.

Our unique vent tube design feature in the purge valves helps to avoid any accidental removal of the stem part of the product during operations

All purge valves are designed to be heat code traceable with the material test report certified as per industry standards

The temperature rating of the purge valves as per their operating parameters is measured to be -54C to around 454⁰C.

Purge valve material of construction: Sealexcel serves as purge valve suppliers and offer high quality industry standard units designed with the SS316 material for construction. The cap, spring, ball and body of the purge valves are designed with the SS316, to ensure high end durability in all pressure industrial conditions.

Purge Valve Industry Applications

Our designed and manufactured purge valves are supplied to a number of sectors of the industry for a variety of applications. These include,

- Instrumentation needs

- Venting

- Some general plant service

- Pneumatic and hydraulic systems

Our testing schedule involves checking and thorough checking of each purge valve unit before it reaches our customers. Every unit is subject to a factory test. We take pride in only offering high quality durable products to our customers, and that is why we ensure that only the flawless unit pieces reach our industrial clients.

At Sealexcel we understand the importance of using the right fitting and valve in an industrial setting, and that is why we never compromise on quality or product featured design.