How to Use a Pressure Gauge with Ball Valve?

February 5, 2023In the realm of plumbing and construction, efficiency and ease of installation are paramount. Traditional methods often require specialised tools, time-consuming procedures, and a certain level of technical expertise. However, the advent of push in fittings has revolutionised the industry, offering a simple and reliable solution for connecting pipes.

What are Push in Fittings?

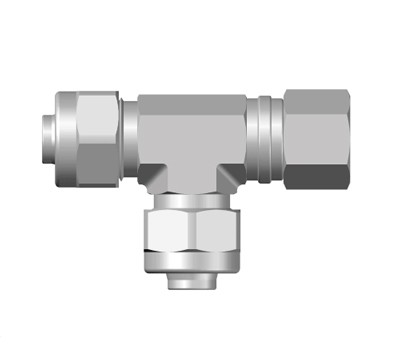

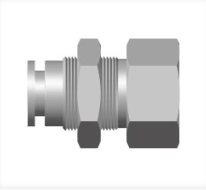

Push in fittings, also known as push-to-connect or compression fittings, are a type of plumbing connector that eliminates the need for soldering or threading. They are designed to be inserted into the pipe with a simple push motion, creating a secure and leak-proof connection. These fittings are typically made of brass or plastic and are available in a wide range of sizes and configurations.

How do Push in Fittings Work?

The mechanism behind push in fittings is relatively straightforward. Inside the fitting, there is a gripping mechanism, often consisting of O-rings and a collet, that securely holds the pipe in place. When the pipe is pushed into the fitting, these components engage and create a tight seal, preventing leakage.

Benefits of Using Push in Fittings

- Speed and Efficiency: One of the most significant advantages of push in fittings is their rapid installation. Unlike traditional methods that can be time-consuming and require specialised tools, push in fittings can be connected in a matter of seconds, saving time and effort.

- Ease of Use: Push in fittings are designed to be user-friendly, even for those with limited plumbing experience. The simple push-and-connect mechanism eliminates the need for complex procedures or specialised tools, making them accessible to a wider range of individuals.

- Versatility: Push in fittings are available in a variety of sizes and configurations, making them suitable for a wide range of applications. They can be used in both home and commercial settings, from minor plumbing repairs to major industrial systems.

- Reliability: Push in fittings are known for their reliability and durability. The gripping mechanism ensures a secure connection, preventing leaks and ensuring the integrity of your plumbing system.

- Cost-Effective: While the initial cost of push in fittings may be slightly higher than traditional methods, the time and labour savings they offer can make them a cost-effective choice in the long run.

Applications of Push in Fittings

Push in fittings have a wide range of applications, including:

- Residential Plumbing: Repairing leaks, installing new fixtures, and connecting pipes in homes and apartments.

- Commercial Plumbing: Maintaining and upgrading plumbing systems in offices, retail spaces, and industrial facilities.

- HVAC Systems: Connecting pipes for heating, ventilation, and air conditioning systems.

- Irrigation Systems: Installing and repairing pipes for watering lawns, gardens, and agricultural fields.

- Pneumatic Systems: connecting pipes for systems that use compressed air in a variety of industries.

Choosing the Right Push in Fittings

The following elements must be taken into account when choosing push-in fittings:

- Pipe Material: Ensure that the fittings are compatible with the type of pipe you are using (e.g., PEX, copper, or CPVC).

- Size: Choose fittings that match the size of your pipes to ensure a proper fit and prevent leaks.

- Application: Consider the specific requirements of your project to select the appropriate fittings for the task.

- Pressure Rating: Ensure that the fittings are rated for the pressure levels in your system.

Installation Tips

- Prepare the Pipes: Ensure that the pipe ends are clean and free of burrs. Use a pipe cutter to create clean, square cuts.

- Insert the Pipe: Push the pipe firmly into the fitting until it reaches the stop. You should feel a slight resistance as the gripping mechanism engages.

- Verify the Connection: To make sure the pipe is firmly inserted, gently push on it after inserting it. If there is any movement, the connection may not be tight enough.

- Inspect for Leaks: Once the fittings are connected, check for any leaks by turning on the water or other fluid. Look for any signs of water or other fluid escaping from the connection.

Conclusion

Push in fittings offer a convenient, efficient, and reliable solution for connecting pipes in various applications. Their ease of installation, versatility, and durability make them a popular choice among homeowners, contractors, and professionals alike. By following the guidelines outlined in this blog post, you can confidently install push in fittings and enjoy the benefits of a well-connected plumbing system.