Coupling Pipes: Enhancing Efficiency in Water Distribution Systems

December 4, 2023

Pneumatic Flow Control Valve: Accurate Airflow

August 13, 2024In the world of plumbing and industrial applications, creating secure and reliable connections is paramount. Leaky pipes can not only be a costly nuisance but also pose a serious safety hazard. That’s where SS Tube Fittings, also known as stainless steel tube fittings, come in. These versatile and durable components offer a robust solution for connecting tubes in a variety of settings.

Why Choose SS Tube Fittings?

There are several compelling reasons why SS tube fittings have become a popular choice for professionals:

- Durability: The strength and corrosion resistance of stainless steel are well known. Unlike some plastic alternatives, SS tube fittings can withstand harsh environments, extreme temperatures, and high pressure. This makes them ideal for long-lasting performance in demanding applications.

- Leak-Proof Connections: SS tube fittings are designed to create a tight seal, minimizing the risk of leaks. This is achieved through various mechanisms, such as compression fittings that utilize ferrules to create a secure grip on the tube, or flare fittings that rely on a tapered design for a perfect seal.

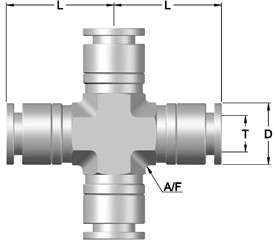

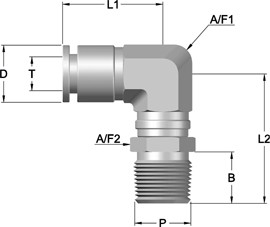

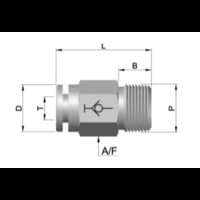

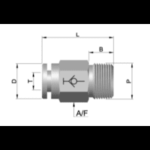

- Versatility: SS tube fittings come in a wide range of sizes and configurations, allowing them to accommodate various tubing diameters and connection types. Whether you’re working with hydraulic lines, instrumentation systems, or air conditioning units, there’s likely an SS tube fitting that perfectly suits your needs.

- Ease of Use: Many SS tube fittings require minimal tools for installation, making them a user-friendly option even for those without extensive plumbing experience. Specific fitting types may have slightly different installation processes, but generally involve tightening a nut or inserting a tube until a secure connection is achieved.

- Aesthetics: Let’s face it, exposed pipes and connections aren’t always the most aesthetically pleasing sight. The sleek and polished finish of SS tube fittings adds a touch of professionalism and cleanliness to any installation, especially important in areas like laboratories or food processing facilities.

Choosing the Right SS Tube Fitting for Your Needs

With the vast array of SS tube fittings available, selecting the right one for your project requires careful consideration. The following are some important things to remember:

- Grade of Material: Not all stainless steel is made equally. Varying grades provide differing degrees of resistance to corrosion. For most applications, 304 stainless steel is a good choice, offering a balance of affordability and durability. However, for environments with high levels of chlorides or other corrosive elements, 316 stainless steel provides superior resistance.

- Tube Size: This seems obvious, but ensuring your chosen SS tube fitting is compatible with the diameter of your tubing is crucial. Mismatched sizes will result in a poor fit and potential leaks.

- Connection Type: SS Tube Fittings come in various connection types, including compression, flare, and weld-on options. Consider the ease of installation, application requirements, and long-term maintenance needs when selecting the ideal connection type.

- Pressure Rating: Different SS tube fittings have varying pressure ratings, indicating the maximum pressure they can withstand without compromising the connection. Ensure the chosen fitting can handle the expected pressure levels within your system.

- Temperature Rating: Similarly, consider the temperature range of your application. Some SS tube fittings are designed for specific temperature ranges to maintain their integrity.

Top Applications for SS Tube Fittings

Top Applications for SS Tube Fittings

The versatility of SS tube fittings makes them suitable for a wide range of applications. Here are some common examples:

- Plumbing Systems: SS tube fittings are a reliable choice for both hot and cold water lines, particularly in commercial or industrial settings where durability and leak resistance are essential.

- Hydraulic Systems: These systems often require high-pressure lines to transfer fluids. SS tube fittings offer the sturdiness needed to withstand the demands of hydraulic applications.

- Pneumatic Systems: Compressed air systems rely on secure connections to maintain pressure and prevent leaks. SS tube fittings provide a reliable solution for these applications.

- Instrumentation Systems: Precision instruments used in various industries require leak-proof connections for accurate readings. SS tube fittings are a popular choice for these sensitive systems.

- Food Processing: Hygiene and cleanliness are paramount in food processing facilities. The corrosion-resistant properties of SS tube fittings make them suitable for these environments, especially for transporting fluids like water, steam, or even food products.

Beyond the Basics: Installation Tips and Maintenance

While SS tube fittings offer a relatively user-friendly installation process, following some basic tips can ensure a secure and long-lasting connection:

- Proper Tube Preparation: Ensure the ends of your tubes are clean, cut squarely, and free of burrs for a perfect fit within the fitting.

- Use the Right Tools: Using the appropriate tools for your chosen SS tube fitting type will ensure proper tightening and prevent damage to the fitting or tubing.

- Don’t Overtighten: While a secure connection is vital, avoid over tightening the fitting as this can damage the threads or the tubing itself. Tighten until snug, then follow any torque specifications provided for your specific fitting type.

- Double-Check Your Work: Before pressurizing your system, take a moment to visually inspect all connections for any leaks or signs of weakness.

Maintenance for Long-Lasting Performance

Like any component in your system, SS tube fittings require occasional maintenance to ensure optimal performance:

- Regular Inspections: Periodically inspect your SS Tube Fittings for any signs of wear and tear, corrosion, or loose connections.

- Cleaning: If necessary, clean the exterior of the fittings with a non-abrasive cleaning agent to remove dirt or grime buildup.

- Tightening (if needed): Over time, some connections may loosen slightly due to vibration or thermal expansion. If you detect minor leaks, carefully re-tighten the fitting per the manufacturer’s instructions. However, frequent retightening may indicate a worn-out fitting or improper installation, and it’s best to consult a professional for replacement.

Conclusion: Building Reliable Systems with SS Tube Fittings

By choosing the right SS tube fittings and following proper installation and maintenance practices, you can build secure, leak-proof connections that form the backbone of reliable plumbing and industrial systems. Their durability, versatility, and ease of use make them a valuable asset for professionals across various industries. So, the next time you’re tackling a project requiring secure and reliable tube connections, consider the many benefits that SS tube fittings have to offer. With their robust performance and sleek aesthetics, they’ll ensure your lines are secure and your project a success.

Top Applications for SS Tube Fittings

Top Applications for SS Tube Fittings