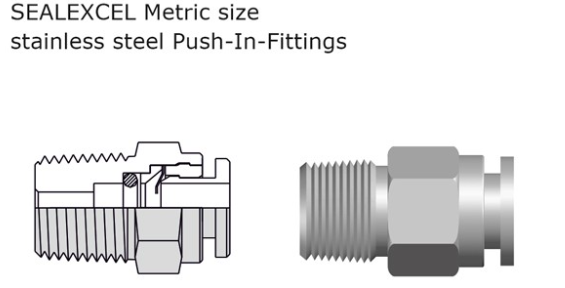

Understanding the Basics of Push to Connect Fittings

Push-to-connect fittings are a revolutionary plumbing innovation that simplifies installation processes and offers numerous benefits. These fittings are designed to provide secure and leak-proof connections without the need for complex tools or soldering. With their user-friendly design and versatile applications, Push to Connect Fitting have become a popular choice in various industries.

How Push to Connect Fittings Simplify Installation Processes

One of the main advantages of push-to-connect fitting is their ability to simplify installation processes. Unlike traditional methods that require soldering or the use of specialized tools, push-to-connect fitting make the connection process quick and effortless. They feature an intuitive design that allows for easy insertion and secure locking, providing a reliable connection every time.

Exploring the Versatility of Push-to-Connect Fittings

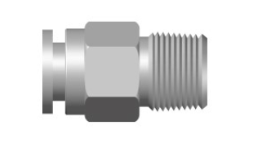

Push-to-connect fitting are highly versatile and can be used with a wide range of piping systems and materials. Whether it’s copper, PEX, PVC, or even stainless steel, these fittings can accommodate various pipe types. This versatility makes push-to-connect fitting suitable for both residential and commercial applications, catering to the diverse needs of different industries.

Enhanced Safety and Reliability

Leak-Proof Connections: Ensuring a Secure Seal Every Time

One of the key advantages of push-to-connect fittings is their ability to form leak-proof connections. This is achieved through several features that contribute to the secure seal and prevent any potential leakage.

The Self-Aligning Feature: Minimizing the Risk of Leaks

Push-to-connect fitting have a self-aligning design that ensures proper alignment of the pipes during connection. This eliminates the risk of misalignment, which is a common cause of leaks in traditional fittings. The self-aligning feature guarantees a secure and tight seal, providing peace of mind and preventing costly water damage.

O-Ring Seals: Providing Additional Protection against Leakage

To further enhance the leak-proof capabilities, push-to-connect fitting utilize O-ring seals. These seals create a tight and reliable seal between the fitting and the pipe, preventing any water or gas from leaking out. The O-ring seals are made of durable materials that ensure long-lasting performance and resistance to wear and tear.

Corrosion Resistance: Ensuring Longevity and Dependability

In addition to leak-proof connections, push-to-connect fitting are also known for their resistance to corrosion. The materials used in these fittings, such as brass or stainless steel, are rust-resistant and can withstand harsh environments. This corrosion resistance ensures the fittings’ longevity and reliability, making them an excellent choice for both indoor and outdoor applications.

Elimination of Fire Hazards: Non-Flammable and Safe Solutions

Traditional plumbing methods often involve the use of open flames and soldering, posing a significant fire hazard. Push-to-connect fitting offer a safer alternative by eliminating the need for open flames and soldering.

Reducing the Risk of Fire Accidents with Push to Connect Fittings

With push-to-connect fittings, the risk of fire accidents is greatly reduced. The connection process does not require any heat, eliminating the potential for accidental fires caused by open flames. This makes push-to-connect fitting particularly suitable for installations in confined spaces or areas where fire safety is a top concern.

Enhancing Workplace Safety by Using Flame-Free Connection Methods

By utilizing push-to-connect fitting, workplaces can prioritize safety and create a flame-free environment for their employees. This is especially important in industries where flammable materials are present or where fire safety regulations are stringent. Push to connect fittings provide a reliable and safe solution without compromising on performance or durability.

Eliminating the Need for Open Flames and Soldering in Installations

Push-to-connect fittings offer the convenience of flame-free installations. Instead of relying on open flames and soldering, these fittings use compression and locking mechanisms to create secure connections. This eliminates any risks associated with flames, making push-to-connect fitting an ideal choice for both professional plumbers and DIY enthusiasts.

Functioning Under High Pressure: Ensuring Reliable Performance

Push-to-connect fitting is designed to withstand high-pressure applications, ensuring reliable performance even in demanding environments. This makes them suitable for a wide range of industrial and commercial applications where high-pressure conditions are common.

Withstanding High-Pressure Applications Effortlessly

Push-to-connect fitting are engineered to handle high-pressure systems without compromising their integrity. The fittings are designed with reinforced materials and robust construction, allowing them to withstand extreme forces without any leaks or failures. This reliability under high-pressure conditions ensures the smooth operation of industrial processes and systems.

Enhanced Performance and Durability in Various Industries

In industries such as manufacturing, oil and gas, or even automotive, push-to-connect fitting offer enhanced performance and durability. They can effectively handle the demanding requirements of these industries, providing a reliable and leak-proof connection that ensures the uninterrupted flow of fluids or gases. This reliability translates into increased productivity and reduced downtime.

Maintaining Consistent Performance in Challenging Environments

Push-to-connect fitting are built to excel in challenging environments where temperature variations, vibrations, or harsh chemicals are present. Their robust design and corrosion-resistant materials allow them to maintain consistent performance in these conditions, ensuring that connections remain secure and leakage-free. This adaptability makes push to connect fittings an excellent choice for applications such as industrial automation, robotics, or heavy machinery.

Summary and FAQs

Summary of the Advantages of Push-to-Connect Fittings

Push-to-connect fitting offer numerous benefits, including simplified installation processes, leak-proof connections, enhanced safety, and flexibility for various applications. These fittings provide efficient and reliable solutions for both professional plumbers and DIY enthusiasts. With their user-friendly design, compatibility with different materials, and versatility in numerous industries, push-to-connect fitting have transformed the plumbing and HVAC landscape, ensuring convenient and reliable connections.

Frequently Asked Questions about Push-to-Connect Fitting

Are push-to-connect fittings compatible with all types of pipes and materials?

Yes, push-to-connect fitting are compatible with various types of pipes, including copper, PEX, PVC, and stainless steel.