All You Need To Know About Purge Valves for Cars

March 20, 2020

Benefits of using Instrument valves and fittings

November 29, 2021Instrumentation manifolds are units containing multiple valves, with numerous connections in one body.

They are used alongside pressure instruments, especially in the plumbing industry.

An instrument manifold valve will, directly and indirectly, help plumbers measure and equalize differential pressures and other variables in process instrumentation lines.

Bleed, block, or calibrate the instrumentation manifolds to make sure the pressure instruments function correctly.

This equipment offers multiple functions and is available in different styles.

Each style suits several applications.

Here’s are the key factors plumbers should consider while shopping for manifolds –

Orientation of the Manifold

In terms of the main body’s orientation, manifolds come with the vertical style manifold and the horizontal style manifold. The orientation of your instrumentation manifold should suit the tasks you wish to accomplish with them. For example, when working with vertical piping arrangements, the vertical style manifold will be more helpful.

The Mounting Technique

Your manifold will have one of two different mounting techniques – direct mounting or remote mounting. With direct mounting, users can mount the manifold directly on their pressure instruments. On the other hand, users can install their remote mounting manifolds far away from their pressure instruments.

No direct contact is required as remote mounting manifolds come with threaded connections. Direct mount valves will feature both threaded connections and flange connections.

The Layout of the Manifold – How Many Valves Do You Need?

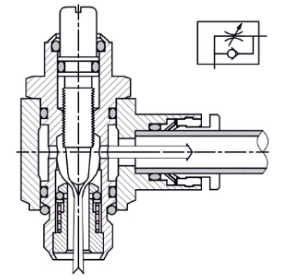

Whether you buy a needle valve manifold or a ball valve manifold, you’ll have to choose between two-way, three-way, or five-way manifold configurations. On single bodies, manifolds come with different numbers of block and isolated valves. The higher the number of valves, the higher the number of openings that permit connections to the pipes (via threaded or flanged connections).

How many block and isolate valves you need will depend on how you want to use the manifold. Here’s a brief guide on how two-way, three-way or five-way instrumentation manifold configurations are used –

- Two-Way Valve Manifold: Also known as the block and bleed valve, this instrumentation manifold is very easy to use. It features one test valve and one block valve. Close the block valve and turn on the test valve. Always Connect the test valve to the pressure generator. Start testing pressure with pressure transmitters.

- Three-Way Valve Manifold: This instrumentation manifold features two block valves and an “equalizer” valve. The equalizer valve is designed to provide equal amounts of pressure on both sides of the manifold. Plumbers typically use this device with differential pressure transmitters. Checking pressure is very easy with three-way manifolds.

- Five-Way Valve Manifold: Like three-way manifolds, five-way manifolds also have two block valves and an “equalizer” valve. These manifolds have two additional valves – the test valve and the vent valve. The technique of using this manifold is similar to using three-way manifolds. Five-valve manifolds are currently the most popular among plumbers who use differential pressure transmitters.

Instrumentation manifolds are vital components. Without them, customizing process lines would be impossible. Use this guide to choose the right type of instrumentation manifold for your pressure instruments.

Sealexcel is the most trusted name in the industry regarding the manufacture and supply of valves, industrial couplings with adapters and fittings.

We have a pan-industry clientele as we conform to industry-standard requirements ensuring safety and system efficiency and robust designs.