Burst Pressure Test

- SEALEXCEL® Well-Lok™ Twin Ferrule Tube Fittings have been tested to tube burst i.e. 4 x permissible working pressure of the tube.

RESULT : No leakage, cracks or damage were detected in the Tube Fittings throughout the test.

- Ensures maximum safety and reliability in high pressure applications.

Why SEALEXCEL® Tube Fitting

Question :

WHY domestic customers still prefer to buy and use internationally renowned brand Swagelok® and Parker A-Lok ® Fittings at very high cost?

Answer :

The locally available Tube Fittings have identical look but may not have important and critical features, hence there are frequent failures. The internationally renowned brand Tube Fittings have important and critical features as shown in features and benefit of Tube Fittings which ensure high safety and consistent reliable performance under adverse, harsh, stressful environments like Vibration, High Pressure, Deep Vacuum and Thermal Shock etc.

Conclusion :

SEALEXCEL® Tube Fittings have all important and critical features which ensures high safety and consistent reliable performance under adverse, harsh, stressful environments like Vibration, High Pressure, Deep Vacuum and Thermal Shock etc.

| FEATURES | SEALEXCEL® VS. SWAGELOK® |

| Twin Ferrules Design | Yes |

| Traceable Quality SS316 | Yes |

| Silver Plated Nut | Yes |

| Hardened Back Ferrule | Yes |

| Thread design to allow Intermix of components | Same |

| Shoulder Marking to distinguish between Metric & Imperial size | Same |

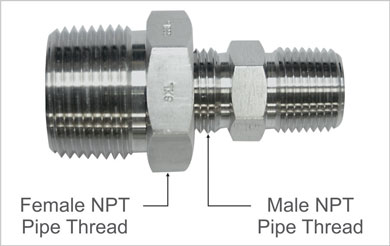

| Ability to Identity different thread from through body marking | Same |

| Stringent Quality Assurance Standard | Yes |

| Installation procedures | Same |

| Gaugeability to check correct installation | Same |

| Pressure Rating | Same |

| Temperature Rating | Same |

| Requirement of Tube Specification | Same |

| Leak Integrity | Same |

What is the main Difference...? THE PRICE !!!

- Trust us.

- Try us.

- Compare us.

- Provide us an opportunity.

- You will be completely satisfied with quality and performance with substantial cost saving.