Revealing the Importance of Flow Control Regulators

June 5, 2015

Choked Flow: Understanding the Physics of Flow Restriction

September 19, 2024Imagine your car’s engine. A symphony of pistons, gears, and valves working in perfect harmony. But what if there was no way to control the flow of fuel and oil? Chaos. The same principle applies to countless industries, from brewing your morning coffee to launching rockets into space. Enter the unsung hero – the flow control valve.

These remarkable devices may seem simple, but they play a critical role in regulating the flow of liquids and gasses within a system. By precisely managing this flow, flow control valves ensure optimal performance, safety, and efficiency.

The Magic Behind the Mechanism of Flow Control Valve

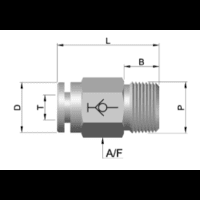

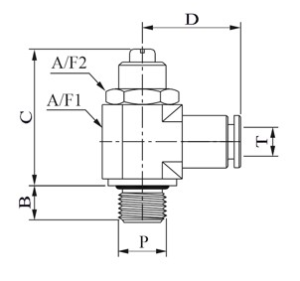

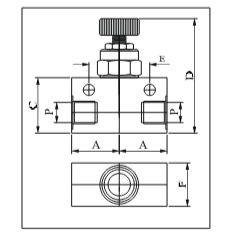

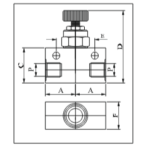

Flow control valves come in various shapes and sizes, but they all share a core concept: restricting the passage of fluid. Imagine a garden hose with a thumb partially covering the opening. The more you cover it, the less water flows through. Flow control valves operate similarly, using internal mechanisms like needles, spools, or discs to adjust the flow path.

A Symphony of Benefits

The benefits of using flow control valves are numerous. Here are just a few:

- Precision Control: Imagine a delicate chemical reaction requiring a specific flow rate. Flow control valves deliver the perfect amount, ensuring consistent and reliable outcomes.

- Process Optimization: In manufacturing, precise fluid flow is essential for efficient production. Flow control valves help maintain optimal speeds for machinery, reducing waste and downtime.

- Safety First: High-pressure systems demand precise control. Flow control valves prevent surges that could damage equipment or pose safety hazards.

- Energy Efficiency: By regulating flow, these valves ensure only the necessary amount of fluid is used, minimizing energy consumption and lowering operational costs.

- Versatility Unbound: From controlling the speed of hydraulic cylinders to regulating water flow in irrigation systems, flow control valves have applications across diverse industries.

Choosing the Right Flow Control Valve

The world of flow control valves is vast, offering a variety of options to suit specific needs. Here are some key factors to consider when choosing the right valve for your system:

- Flow Rate: This refers to the amount of fluid the valve can handle per unit of time. Choose a valve with a capacity exceeding your system’s requirements.

- Pressure Rating: Consider the maximum pressure within your system. Selecting a valve with an appropriate pressure rating ensures safe and reliable operation.

- Fluid Type: Different fluids have varying properties. Choose a valve material and design compatible with the fluid being used.

- Control Mechanism: Flow control valves offer manual, automated, or pressure-compensated control options. Select the one that best aligns with your system’s needs.

Investing in Precision

Flow control valves may seem like a small detail, but their impact is undeniable. By ensuring precise fluid management, they contribute to a smoother, safer, and more efficient operation across industries. So next time you witness a perfectly brewed cup of coffee, a smoothly operating hydraulic press, or a flawless rocket launch, remember the silent hero behind the scenes – the flow control valve.

Beyond the Basics

This blog has merely scratched the surface of the fascinating world of flow control valves. From advanced designs like proportional and servo valves to their role in cutting-edge applications like robotics and renewable energy, there’s much more to explore.

Do you have any questions or experiences with flow control valves? Share them in the comments below! Or visit our website www.sealexcel.com