Tube Fittings: Understanding the Major Differences

December 2, 2022

What Are Stainless Steel Pipe Fittings?

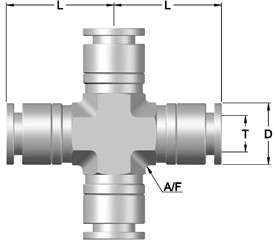

December 2, 2022A quick exhaust valve (QEV) is a type used to release air or other gases from a system. The quick exhaust valve is designed to open and close quickly, allowing it to release a large volume of air or gas quickly. Quick exhaust valves are used in various applications, including pneumatic systems, air compressors, and vacuum pumps.

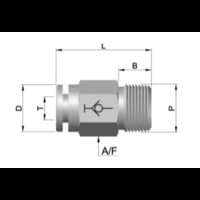

Quick exhaust valves are used on high-performance engines to allow the exhaust gases to leave the engine quickly, providing increased performance. They are also used on turbocharged and supercharged engines to help reduce lost power and boost performance. Proper installation of quick exhaust valves is important for optimal performance. Quick exhaust valves can be expensive, but they are worth the investment if you want to improve your engine’s performance.

How does a quick exhaust valve work?

A quick exhaust valve (QEV) is a type used to release air or other gases from a system. The quick exhaust valve is often used in pneumatics, which uses pressurized gas to power machines. The quick exhaust valve is designed to open quickly, which allows the air or gas to be released quickly. The quick exhaust valve is often used in pneumatic systems that require high-speed operation.

What are the benefits of using a quick exhaust valve?

A quick exhaust valve is used to release pressure from a system quickly. Quick exhaust valves are often used in pneumatic systems, where they are used to release the air pressure that is used to power the system. Quick exhaust valves are also used in hydraulic systems, where they are used to release the fluid pressure that is used to power the system. Quick exhaust valves are typically used in applications where it is necessary to release pressure very quickly, such as in emergencies.

What are the drawbacks of using a quick exhaust valve?

While quick exhaust valves have some advantages, there are also some potential drawbacks. One is that they can be quite noisy because they are constantly venting air. Additionally, they can potentially waste air if not used properly. Finally, they can be less reliable than other valves, as they are more likely to stick or leak over time.

How can I choose the right quick exhaust valve for my application?

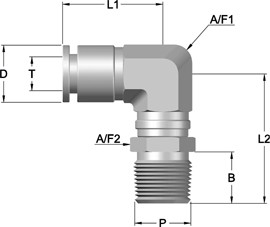

When choosing a quick exhaust valve, it is important to consider the specific application to select the most appropriate valve. Several types of quick exhaust valves are available on the market, each with its own strengths and weaknesses. For example, diaphragm-type quick exhaust valves are well-suited for applications where space is limited, but they may need help to handle large exhaust flow rates.

Piston-type quick exhaust valves, on the other hand, can handle larger exhaust flow rates but may be less precise than diaphragm-type valves. It is also important to consider the material of the quick exhaust valve, as different materials are better suited for different applications. For example, stainless steel quick exhaust valves are often used in food and beverage applications, while aluminum quick exhaust valves are often used in pneumatic applications.

Quick exhaust valves are used to release air from a system quickly. They are often used to release air from a cylinder so that it can be retracted quickly. Quick exhaust valves also release air from a system so it can be depressurized quickly.