Types of valves and its application

April 5, 2016Different types of industrial valves and its functions

April 26, 2016Tube Fittings have an immense industrial application. It is due to these fittings that the assembly is able to function in a leak free manner. It goes beyond doubt that their continued usage may result in their wear and tear. Since, these fittings of tube are imperative for the system, hence their replacement requires a plethora of norms to be considered. They are available in a variety of designs and constituent.

In order to choose with respect to their application, the following parameters need to be considered:-

- Design- it is imperative that the material which constitutes the fittings has anti corrosive qualities. It is only due to such anti corrosive qualities that the longevity of the system can be assured. There are such designs which are associated with locking capacity. This is imperative for stringent assembles. Hence, make sure that the design you are employing has comprehensive design and precision. It is important to consider the thickness of the walls as well as the diameter in order to reach to a conclusion with respect to it.

- Temperature- There is much number of industrial applications of the fittings as well as the Tube Adaptors. It is imperative that you decide on the same in accordance with the temperature range applicable. This in turn will depend on the type of material used, plating and the seal. Hence, care needs to be taken. If you need the fitting for a high temperature range, those comprising lock, nut and ferrule made from high quality steel alloys, provide a tight fit. Thus, these prove optimum for heat tolerances.

- Pressure rating- you have to make sure that what pressure your system or assembler will be able to withstand. It is better to choose the fitting whose pressure withholding capacity is preferably higher than the expected pressure of the system. At the same time you cannot ignore the potential shocks a system may experience. It is the best gauge for selecting fittings that will pursue under pressure.

- Media- You need to be sure about the media used in the system, for which you are employing the fittings. It will be useful to check the compatibility tables for the same. You are also required to check with the corrosion resistance of the gas or fluid media that is transported. There are fittings which are coated with a protective layer for higher usability.

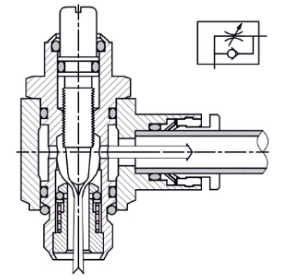

It is also important for you as the user to ensure that the best quality material is utilised. Many application areas use these fittings along with Needle Valves. Their design, size and constituent also needs to be considered. The valves have a wide usage in the shuttling of the flow of liquid and gases. Hence, they make an indispensable part of industrial process.

Hence, whatsoever be your requisite it is mandatory to take care of all the aspects of industrial application. It will be an advantageous aspect. It is bound to pursue the process in an excellent manner. The reviews and feedbacks of the manufacturer also need to be considered.

S.V. Road, Oshiwara,

Jogeshwari (West ),

Mumbai

Pin Code – 400102

INDIA.