Seal Excel is the leading manufacturer of pneumatic fittings in India. We provide a diverse selection of precisely engineered & NSF-approved pneumatic fittings for connecting pipe, tube, and hose sections. Our team of Pneumatic Fittings experts with extensive knowledge works hard to bring you an incredible selection of pneumatic fittings at affordable prices. Our goal is to provide our customers with high-quality pneumatic fittings. We are one of the leading pneumatic fittings manufacturers because of our constant efforts to introduce top-notch quality and our relentless pursuit of excellence.

Top-notch & Reliable Pneumatic Fittings

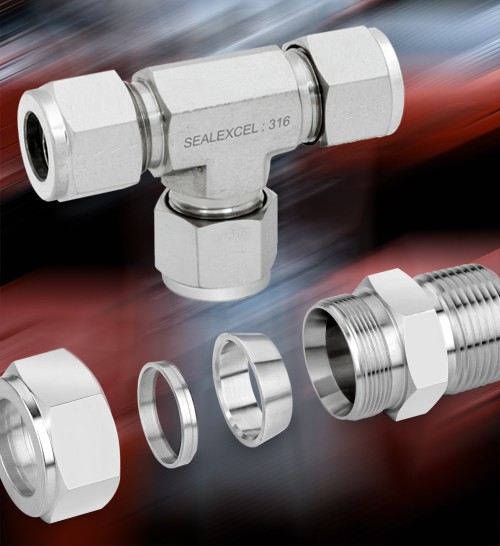

Seal Excel is one of India's most reputable pneumatic fittings manufacturers and is well-known for its precision pneumatic fittings and attention to detail. We manufacture and offer a well-thought-out collection of Pneumatic fittings, which come in a variety of shapes and sizes, as well as a variety of connection types and purposes. Following is the list of our Pneumatic Fittings

- Stainless Steel Push-in-Fittings

- Stainless Steel Push-on-Fittings

- Quick Connect Couplings

- Flow Control Regulators

- Quick Exhaust Valves

- Precision Pipe Fittings

- Pneumatic Check Valves

- Needle Valves

- 2/3 Way Ball Valves

Uses of Pneumatic Fitting

Production lines

Pneumatic fittings are used in a broad range of sectors and applications, including construction, assembly, production line settings, and a wide range of industrial machines, handheld tools, and workstation equipment. A pneumatic fitting's versatility, reliability, cost-effectiveness, and safety may frequently outperform a comparable arrangement driven by different electric motors and actuators in many industrial environments.

Control of Airflow

Pneumatic fittings are the vital connection between tubes, hoses, and other pneumatic system components. Air fittings have tighter seals and less pressure than hydraulic fittings and are usually available in various connection types. Miniature fittings regulate airflow pressure and directional flow, connect our pneumatic fittings, and halt unused ports' flow.

Energy Consumption

Although the pneumatic couplers are the smallest components of the total pneumatic system design, they are arguably the most essential. Pneumatic fittings, together with their pipes, hoses, and tubes, link all of the other main components and, therefore, have a significant impact on the system's overall efficiency, safety, and energy consumption.

Because pneumatic fittings are in charge of sending the correct quantity of compressed air where it needs to go, choosing the appropriate one is critical. As a result, there is a huge range of sizes and forms. Straight fittings and elbow fittings are common, as are more complicated cross fittings, branch fittings, valves, and other items. Air fittings are characterised by their compression technique, how they join, material make-up, and how they are barbed in addition to their overall form or purpose.

Suited For Numerous Applications

Our pneumatic fittings are suitable for various applications and are not limited to industrial use. Seal Excel pneumatic fittings can be used in a range of situations in your daily lives, including:

- Automatic devices

- Laboratories (Medical, Pharmaceutical, etc.)

- Instrumentation

- General Plant Service

- Instrument Isolation

- Hydraulic and Pneumatic

- Pressure measurement devices

- Venting

- Instrument Airlines

- Low Pressure Instrument Lines

- Beverage Machine

Precision-Engineered Pneumatic Fittings from Sealexcel – A Leading Manufacturer in Mumbai

When it comes to achieving efficient pneumatic systems, the quality of your fittings is paramount. As a trusted pneumatic fittings manufacturer in Mumbai, Sealexcel delivers a robust range of high-performance components tailored for demanding industrial applications. Our fittings are designed for reliability in automation systems, cleanroom environments, and compressed air lines.

At Sealexcel, we understand the importance of durability and performance. That’s why our fittings are manufactured using premium materials such as stainless steel, each tested for strength, corrosion resistance, and sealing integrity. Whether you're building a new system or upgrading an existing one, our fittings offer secure connections and long service life.

Our stainless steel air fittings are ideal for industries requiring hygienic conditions and long-term durability, including food processing, pharmaceuticals, and chemical handling. These fittings are engineered to meet stringent quality standards while withstanding high pressures and harsh operating environments.

With decades of experience and a strong focus on engineering excellence, Sealexcel has become a preferred supplier for OEMs and system integrators across India and beyond. As your go-to pneumatic fittings manufacturer in Mumbai, we are committed to delivering consistent quality, technical support, and dependable product performance.

Explore our complete pneumatic fittings portfolio and experience the Sealexcel difference in industrial connection solutions.

FAQs

What are the different types of pneumatic fittings?

Different types of NSF certified pneumatic fittings are push-in, push-on, flow control regulators, pneumatic check valves, quick couplings, etc.

What are pneumatic fittings made off?

Pneumatic fittings are made up of Stainless steel.

How are pneumatic fittings measured?

The size of the vessels to which a pneumatic fitting connects determines its size. The inside diameter (ID) and exterior diameter (OD) of tubes, hoses, and pipes are measured in inches (in) or millimetres (mm).

How do you connect pneumatic fittings?

To connect pneumatic fittings, look at the hose of application by pushing it into the fitting's release ring-end until it stops. The internal lock claws will automatically clamp around the hose for a quick and secure connection.