Quick Exhaust Valve: Common Troubleshooting Problems and Solutions

February 24, 2024

Pneumatic Pipe Fittings: Simplify Installation and Maximize Operations

March 6, 2024Introduction:

In the world of industrial automation and compressed air systems, pneumatic pipe fittings play a critical role in ensuring efficient and safe operation. These seemingly simple components are responsible for connecting pipes, hoses, and various equipment, forming the backbone of the entire pneumatic network. While the temptation might be to choose the most cost-effective option available, opting for high-quality Pneumatic Pipe Fittings offers a multitude of benefits that far outweigh any initial cost savings.

The Importance of Pneumatic Pipe Fittings:

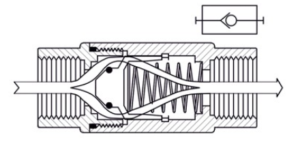

Before diving into the specific advantages, it’s crucial to understand why pneumatic pipe fittings are so crucial. Compressed air systems power a vast array of industrial applications, from powering actuators and robots to controlling valves and operating tools. Pneumatic pipe fittings ensure the smooth flow of this compressed air by creating secure and reliable connections throughout the system.

Benefits of Using High-Quality Pneumatic Pipe Fittings:

- Enhanced System Reliability: High-quality pneumatic pipe fittings are manufactured with robust materials and precise tolerances. This ensures a secure and leak-free connection, minimizing downtime and production losses from air leaks and system failures. Additionally, these fittings are resistant to corrosion, wear and tear, and harsh operating conditions, leading to a longer lifespan and reduced maintenance costs.

- Improved System Efficiency: Leaks in a pneumatic system can significantly impact its efficiency. High-quality pneumatic pipe fittings provide a tight seal, preventing air loss and ensuring that the full working pressure reaches the intended equipment. This translates to better performance, increased productivity, and lower energy consumption in the long run.

- Increased Safety: In a pneumatic system, pressure plays a vital role. Leaks and faulty connections can lead to pressure fluctuations and uncontrolled releases of compressed air, posing a safety hazard to personnel and nearby equipment. High-quality Pneumatic Pipe Fittings are designed to withstand the required pressure ratings, minimizing the risk of accidents and ensuring a safe working environment.

- Simplified Installation and Maintenance: Well-designed and user-friendly pneumatic pipe fittings typically offer easier installation and maintenance compared to their lower-quality counterparts. This can save valuable time and resources during initial setup and future maintenance procedures, further contributing to overall system efficiency.

- Reduced Long-Term Costs: While the initial cost of high-quality pneumatic pipe fittings might be higher, the long-term benefits outweigh this initial investment. These fittings offer increased reliability, improved efficiency, reduced maintenance needs, and a longer lifespan, leading to significant cost savings over time.

Choosing the Right Pneumatic Pipe Fittings:

With a diverse range of pneumatic pipe fittings available in the market, selecting the right ones for your specific application is crucial. Consider factors like:

- Material: Choose fittings made from durable materials like brass, stainless steel, or high-performance polymers, depending on the operating pressure, temperature, and environmental conditions.

- Size and Compatibility: Ensure the fittings match the pipe and hose diameters in your system and are compatible with the chosen connection method (e.g., threaded, push-to-connect, etc.).

- Pressure Rating: Select fittings with a pressure rating exceeding the maximum operating pressure of your system to ensure safety and prevent failures.

- Application: Consider any specific needs your application might have, such as high temperature resistance, corrosion resistance, or quick-disconnect functionality.

Conclusion:

Investing in high-quality Pneumatic Pipe Fittings might seem like an additional expense at first, but the long-term benefits far outweigh the initial cost. These fittings offer enhanced system reliability and efficiency, improved safety, easier maintenance, and ultimately, a significant reduction in operating costs. So, when building or maintaining your compressed air system, prioritize quality over cost and reap the numerous advantages of using high-quality pneumatic pipe fittings.